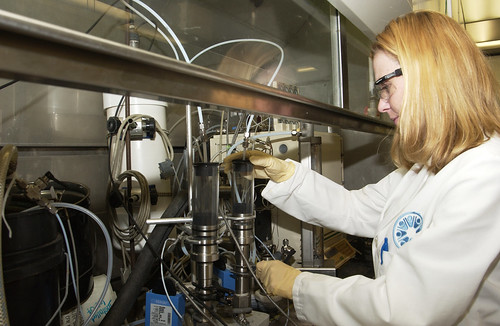

Engineering Debate: Plane Bearings Vs Ball Bearings For Heavy Loads รูปภาพ เทคโนโลยี อุปกรณ์ อุตสาหกรรม เครื่องจักร แขน วิศวกรรม

The main task of bearings is to enable defined movements of components and thereby reduce friction as much as possible Learn about load types, clearance, and fit to optimize performance in industrial applications. Although both types of bearings have a common goal, there are fundamental differences in design, functionality and application

Automatisering Ingenieurs - Gratis afbeelding op Pixabay

This blog article describes the most important differences between ball bearings and plain bearings. Selecting right bearings ensures efficiency and longevity How do sealed bearings benefit heavy equipment applications

Sealed bearings offer superior protection against dust, moisture, and debris—common in construction and mining—extending the lifespan of industrial bearings for heavy loads

Explore the plain bearings vs ball bearings in load capacity, friction, and precision between plain and ball bearings for informed choices. Precision in motion now, let's shift our focus to ball bearings These engineering marvels utilize multiple balls enclosed in steel cages to maintain separation between moving parts Ball bearings find their homes in applications like hard drives, roller skates, and door hinges, thanks to their ability to reduce rotational friction and support both radial and axial loads

Bearings are essential components in a variety of machinery, from industrial equipment to automotive systems When choosing the right bearing, two popular options come to mind Plain bearings and ball bearings While both perform similar functions, their design and application are vastly different, making them suitable for specific scenarios.

Compare roller bearing vs ball bearing to see which suits heavy loads or high speeds

Find key differences and best uses for your machinery needs. Ball bearings are used across a wide range of industries and applications due to their ability to reduce friction and support radial and axial loads Below are some of the most common applications Automotive industry ball bearings are integral components in automotive systems, used in wheel hubs, transmissions, and engines.

Discover the different types of bearings — ball, roller, slewing, plain, linear, and mounted bearings — and learn how to select, use, and maintain them for optimal mechanical performance This comprehensive guide helps engineers and purchasing professionals choose the right bearing for every application. Ball bearings, composed of spherical rolling elements, carry loads with point contact between balls and raceways They are versatile and used in numerous applications requiring a balance of radial and axial load support, but are optimal for lighter loads.

Brief overview of bearing load importance understanding bearing loads is key to mechanical systems that depend on precise load determination for performance and bearing life

Bearings efficiently handle predicted forces without causing undue stress, deformation, or wear when axial, radial, combined, and centrifugal loads are accurately calculated. Journal bearing clearance, also known as bearing play, is the gap between the shaft and the bearing surface when the bearing is not under load The clearance is a critical parameter that directly impacts the performance and reliability of journal bearings. Explore the crucial roles of radial, axial, and centrifugal bearing loads and their impact on machinery efficiency and lifespan.

If misalignment is a concern, spherical roller bearings provide the best solution Conclusion both ball bearings and roller bearings play vital roles in various mechanical systems Understanding their differences in design, load capacity, speed capability, and durability is crucial for selecting the right bearing for your application. Learn how bearings are essential for smooth mechanical operations.

Ball bearings are used for controlling oscillatory and rotational motion

For example, in electrical motors where the shaft is free to rotate but the motor housing is not, ball bearings are used to connect the shaft to the motor housing Depending on the application, different types of ball bearings are available to choose from. Affordable, lightweight, and compact, plain bearings come in handy when rotational or slide movement for heavy loads is needed. Double row ball bearings support heavy radial loads, thrust loads from either direction, or combined radial and thrust loads

They are normally used in positions where radial loads exceed the capacity of a single row bearing with a comparable bore and od. In this blog post, we discuss types of existing bearings Ball bearing, plain bearing and roller bearing Bearings are constantly improving, as manufacturers endeavour to minimize friction in different load cases.

Study with quizlet and memorize flashcards containing terms like doubling the load on a bearing increases its service life by 6 to 8 times., a better finish on a bearing produces less friction., ball bearings are installed with one ring being a press fit and the other a push fit

For high speeds with low loads and excessive vibration scenarios Ball bearing thrust bearings are mainly for high axial loads, whereas ball bearings are mainly for radial loads The structure of the ball or other rolling element arrangement includes an alternative positioning between two rings. In this article, we reveal the main differences between sleeve bearings and ball bearings