Machinist Debate: Is 33/64 Still The Best 9 16 X 18 Tap Drill Size? Sizes Engine Pro

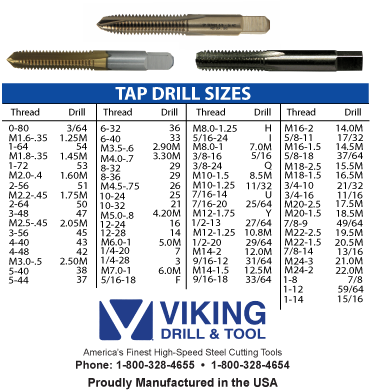

The recommended drill bit size for a 9/16 tap is 33/64 inches, slightly smaller than the tap, to ensure proper thread depth and a secure fit Covers unc, unf, and metric thread sizes to ensure accurate, reliable threading. Precision is key when working with a 9/16 tap to prevent thread stripping and ensure a strong connection between mating parts.

Tap Hole Size Chart for Hobby Machinists | The Hobby-Machinist

Tap drill size calculator for inch and metric threads (for cutting and forming taps) Find the right drill bit for any tap with this complete tap size chart Plus formulas and charts for tap drill size.

The tap drill size depends on the thread type and diameter

Using the right tap drill size helps you get the best core hole sizes, dimension,s and strong threads. Unit conversion calculator to convert the following units acceleration, area, torque, electrical, energy, force, force / length, length, light, mass, mass flow. Comprehensive tap size chart for manufacturing and machining Includes fractional, metric, and numbered screw sizes, decimal equivalents, pitch, and recommended tap drill sizes for threading operations.

Tap drill size size formula's are theoretical based on the thread type and desired percentage of thread Please allow for the fact that drills generally drill oversize. Precision cut threads, accurately formed for consistent, exact threading heat treated and tempered for file hard threads and longer useful life designed for hand cutting applications the plug style tap is the most commonly used style of tap with 3 to 5 threads chamfered best drill 33/64″ use with cutting oil when cutting threads in metal.

Screw/thread size, major and minor diameter, drill size, decimal equivalent

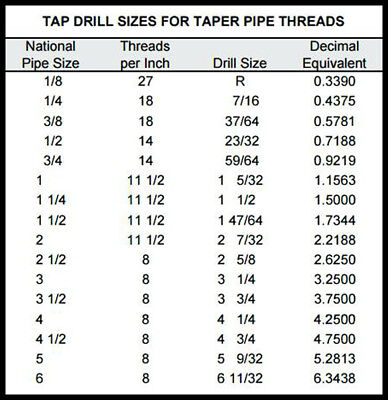

Tapped hole, close fit, and free fit clearance holes. Comprehensive drill size chart for manufacturing and fabrication Includes fractional, metric, wire gauge, and letter drill bit sizes with decimal equivalents for quick reference. Printable tap and clearance drill sizes chart screw size majordiameter threadsper inch minordiameter t

Therefore the tap drill chart is extremely important To create a thread properly, one would need a set of three taps that correspond to the same bit size Namely the bottoming, the intermediate, and the taper tap Drill bit size chart guide with fractional, metric, number, and letter sizes

Learn how to choose the right drill bit for wood, metal, and masonry.

Another method for determining the clearance hole size is to use the recommended minor diameter of the bolt and add a clearance allowance. The tap drill size of a hole that will be cold form tapped is usually bigger than it cutting tap counterpart (77% thread is what you want to use) a 100% thread is 3/4 qtr, or (6/8 th), of the full 60° triangle which is the maximum allowed height of a full thread, the v shape, including flats. Armstrong metalcrafts does prototyping and produces devices that stimulate the imagination, spark a conversation, and enlighten the soul.

It covers both inch and metric size drills Most commonly used in the us, but can still be found occasionally in the uk, these imperial measurement drill bits come in 1/64 inch increments The fractions used are always in their simplest form, i.e Reduced as far as possible, so 2/64 becomes 1/32 for instance

The drill size chart below gives fractional sizes and their metric conversions up to 1 inch.

Machinist drilled hole tolerance capabilities chart per Tool sharpness, accuracy, tool and machine rigidity, machine spindle bearings wear.