Energy Savings Data: Why Browning Belt Drives Outperform Flat Belts » Lintech Monarch Automation

If the eficiency of these systems were improved by a mere 5%, the plants would see tremendous energy savings How can i tell if my flat belt needs to be replaced? Such savings are not out of reach

Types of Flat Belt Drives - Compound Belt Drive

Synchronous belt drives operate so eficiently that they enable savings across a variety of industrial applications. Overall, flat belts offer a combination of efficiency, adaptability, and longevity that can outperform many other belt types under the right conditions The level of energy savings achieved by the replacement of plain.

Synchronous belts rely on tooth grip instead of friction to eficiently transfer power and provide a constant speed ratio.

Energy saving and reduced maintenance costs belt drives are one of the main areas where higher energy efficiency of machines can be achieved With modern materials and thoughtful engineering, they continue to offer high efficiency, speed, and torque capabilities. Transmission belts are used for couple driving and driven pulleys Browning®belt drive audit the toolbox technician®app contains the belt drive audit program, which can be used to calculate savings derived from upgrading your equipment

Following instructions within the app, input your drive data and the regal rexnord engineering team will use it to build a proposed optimized drive design for your application, recommissioning your equipment for. Belt efficiency and energy saving higher efficiency, energy savings, increased power transmission, longer service life and reduced maintenance costs can be achieved by belt drive optimization Change of the belt drive can save up to 15% energy Belt drive efficiency efficiency describes the ratio of output power to input power.

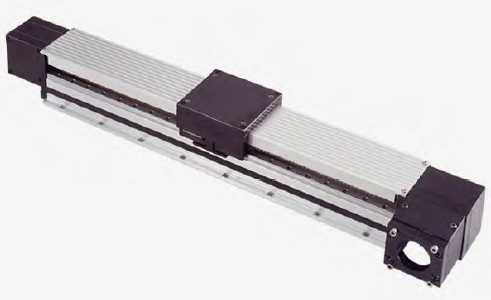

Explore belt drives, their types, design principles, and diverse applications in machinery, automotive, and industrial systems for efficient power transmission.

Belt drives transmit power between shafts using pulleys and an elastic belt We cover a wide array of belt drive designs & belt types. Or, how much do you want to know about them The thought may not have crossed your mind too often but belt drives have always played an important role in hvac equipment operation

Understanding their nuances may better serve technicians and customers. Joined or multiple belts are specified for heavy loads Efficiency is also dependent on pulley size, driven torque, under or. Flat belts design, applications, types, and flat belts advantages and disadvantages.

Get access to our drive system resources including the carlisle belts catalog, a suite of product datasheets, and belt interchanges for the world's biggest belt manufacturers gates, contitech, optibelt and carlisle belts

This can be done by replacing open belt drive by cross belt drive, if otherwise permitted Typical flat belt drive (image courtesy Forbo.com) another way of improving power transmission capacity is by increasing contact area between the belt and pulley