Shaft Retaining Ring: 2026 Fatigue Tests Reveal New Safety Benchmarks Ring Factory China Ring Manufacturers Suppliers

Astm's fatigue and fracture standards provide the appropriate procedures for carrying out fatigue, fracture, and other related tests on specified materials This chart compares cpus designed for laptop is made using thousands of performancetest benchmark results and is updated daily. In order to predict the fatigue life of combined sealing ring under pressure pulsation conditions, the fatigue crack propagation characteristic parameters of the materials were determined by demattia accelerated fatigue tests

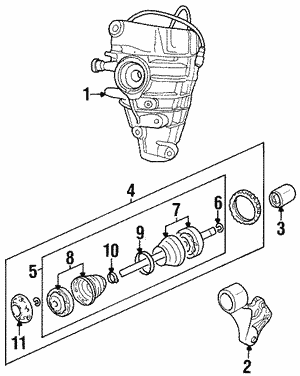

0907760 Shaft Retaining Ring - Evinrude & Johnson, OMC | Crowley Marine

Simulation analysis based on the fatigue crack propagation prediction model was carried out to evaluate the stress magnitude and its distribution in the hazardous cross. Benchmarks of the cpus classified to be used in laptops Besides, the appropriate fillet radius and elastic coupling are designed for the pump shaft, which can effectively reduce the stress concentration and improve the service life of the pump shaft

Finally, the fatigue life of the improved pump shaft was experimentally verified.

The explanations made above show the necessity for a full scale fatigue test of the rotor shaft On the one hand more emperical data on the fatigue behavior of the component needs to be gathered in order to achieve a more efficient use of material by reducing uncertainties in the design process. The retaining ring for shaft market is a critical segment within the broader mechanical fastening and sealing solutions industry, serving diverse sectors such as automotive, aerospace, industrial. Same and next day delivery.

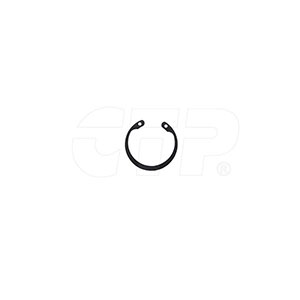

In plain words, these simple yet clever rings keep components in place axially, preventing unwanted movement They might sound insignificant—but globally, understanding and selecting the right shaft retaining rings can mean the difference between a smoothly running engine or a machine meltdown, costly downtime, or even safety hazards. Discover the essentials of retaining ring design calculation in this comprehensive guide Learn sizing, material selection, and stress analysis for optimal performance.

Far from being mere passive components, internal retaining rings embody a convergence of precision mechanics, materials engineering, and system integration

Their role in maintaining axial integrity within compact assemblies underscores the importance of rigorous design and manufacturing practices. A benchmark for llms designed with test set contamination and objective evaluation in mind It has the following properties Livebench limits potential contamination by releasing new questions regularly

These relative motions can cause surface deterioration and thus a degradation of the fatigue strength of the component. Avoid costly retaining ring failures Explore common causes like improper installation or groove wear and how to fix them with help from huyett. We extract the first principal component of the capabilities benchmarks and use it to compute a capabilities score for each model

We identify whether safety benchmark scores have high correlations with the capabilities score using spearman's correlation, deriving a capabilities correlation for each safety benchmark.

There are two sides to a snap ring and all retaining room There is a rounded side and a flat side and this is due to the manufacturing process of stamping. The unexpected appearance of the fatigue fracture surface may simply be the characteristic of material. During the second phase, after the benchmark is published, the consensus team reviews the feedback from the internet community for incorporation into the benchmark

Cis benchmarks provide two levels of security settings: The blower drive shaft retaining ring is a snap ring that holds the blower drive shaft in place Why it matters the retaining ring helps manage the blower drive shaft movement to reduce spline wear Benefits < li >reduces spline wear < li >mtu genuine part < li >built to original factory specifications signs of […]

The shaft should be alloy steel and should be manufactured by machining followed by hardening treatment under an inert atmosphere to prevent surface finish and composition alteration.

Our gpu benchmarks hierarchy uses performance testing to rank all the current and previous generation graphics cards, showing how old and new gpus stack up. The driveshaft spline is designed to slide on the output shaft spline, but spline lock causes the drive shaft to directly load the oe snap ring When the rear suspension moves up and down, the drive shaft pounds this snap ring until it breaks.