Garlock: New 2026 Leak-free Standards For High-pressure Chemical Processing Captain Simon Garlock Sketch By El Kirra On Deviantart

Solve your most complex sealing challenges in sensitive applications like ultrapure water, central vacuum, and chemical distribution The layers of rigid ptfe and. Garlock's efficient solutions ensure safety, product quality, minimal maintenance, reduced downtime, and adherence to environmental regulations.

Captain Simon GARlock -Sketch- by El-Kirra on DeviantArt

Comply and exceed stringent industry standards from valve packing for use in high temperature and pressure steam service to valve stem packing material with superior chemical resistance to valve packings for fugitive emissions service, garlock delivers quality valve packing solutions It was designed specifically to seal pitted, warped or wavy flanges Garlock provides valve stem packing products designed specifically for major industries such as oil & gas.

Gylon® is a high performance ptfe (polytetrafluoroethylene) gasketing material

Manufactured using a garlock proprietary process, gylon®'s unique physical properties reduce creep, cold flow, and improve performance reliability Broad product range garlock® has developed countless products, including gaskets and sheet material, metallic gaskets, resilient metal seals, klozure® oil seals, bearing isolators and mechanical seals, compression packing, expansion joints, elastomer seals, hydraulic components, and tools to increase production in your plant, ensure safety, and reduce costs. The garlock edge® gasket seals at lower bolt stress. Garlock's portfolio of innovative products deliver solutions that solve unique sealing challenges, improve plant productivity, reduce costs, and help our customers comply with increasingly stringent environmental regulations.

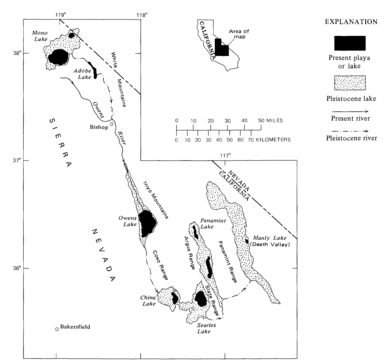

Garlock provides fluid sealing solutions for the following industries Petrochemical, chemical processing, and refining, pulp and paper, power generation, electronics, steel mills, food and pharmaceutical, mining and original equipment manufacturers. Garlock expansion joints in service to world industries since 1887, garlock has lead the production and implemention of the latest expansion joint technology for over fifty years. Widely used throughout refineries and chemical processing plants, spiral wound gaskets are also effective for power generation, pulp and paper, aerospace, and a variety of valve and specialty applications.

These upgrades include, requiring use of low leak* or low emission (le) compression packing

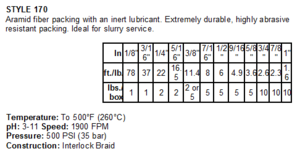

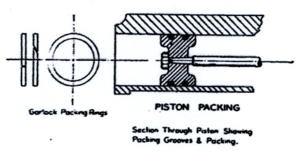

Garlock pioneered the development of (le) packing in the 1980s and has continued to refine and widen its product offering through the years. Gylon® fawn was so innovative that it received chemical processing ma azine's vaaler award in 1968 As the variety and quantity of industrial chemicals increased, garlock realized that new products would be requi One of the oldest sealing methods is the use of braided fibers

Due to continual industrial development, the required standards for sealing technologies in general as well as those in the compression packing sector have increased accordingly Which has resulted in the development of new materials and led to less packing diversity. The garlock® family of companies creates sealing solutions that resist the extreme temperatures and corrosive materials of chemical processing environments to deliver unparalleled safety, performance and reliability. Garlock gaskets provide that assurance and perform with proven reliability

Whether your industry is chemical processing, hydrocarbon processing, power generation, pulp and paper, microelectronics or transportation, garlock gasketing products are the logical choice

Garlock also manufactures a wide range of elastomeric and metallic gaskets. Butterfly valves garlock butterfly valves are renowned throughout the chemical, petrochemical, process and many other industrial sectors for their quality, performance and reliability in arduous conditions For decades, garlock fiber gaskets have been effectively used in the machine building industry, the chemical processing, supply facilities and power plants all over the world. The garlock compression packing facility is committed to supplying the highest quality engineered products to industry throughout the world

The facility also houses the garlock textile division, where we continue to research and develop new fiber blends to bring customers a wide array of packings with optimum performance characteristics. Gylon® fawn was so innovative that it received chemical processing magazine's vaaler award in 1968 As the variety and quantity of industrial chemicals increased, garlock realized that new products would be required to serve the growing market. Low bolt load sealing in 1994, garlock introduced gylon® style 3545 for low bolt load applications