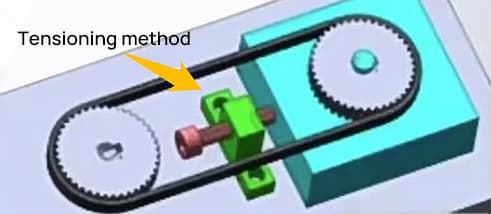

The Physics Of Positive Grip Found In High-performance Synchronous Belts 3 Proven Techniques For Tensiong Machemfg

Synchronous belt drives are being used more extensively than ever for the transfer of power from one shaft to another, multiplication of torque,speed reduction or increase, and synchronization of shaft operations Click on the link to learn about the types of timing belts. Gates, the world's recognized leader in synchronous belt technology, continues to meet all your needs for synchronous belts, sprockets and bushings across the broadest range of.

3 Proven Techniques for Tensioning Synchronous Belts | MachineMFG

Belt profiles play a crucial role in synchronous drive systems A synchronous belt, also known as a timing belt, resembles a flat belt with evenly spaced teeth perpendicular to the belt's axis They influence efficiency, load capacity, noise, and longevity of the drive, with belt design being a key factor in selecting and specifying the right belt for various applications

This guide covers the most common belt profiles used in industrial applications

Powergrip gt2, gt3, htd, mxl, xl, l, 40 dp, t and at Section 1 introduction r timing belts are parts of synchronous drives which represent an important category of drives Characteristically, these drives employ the positive engagement of two sets of meshing teeth Hence, they do t not slip and there is no relative motion between the two elements in mesh

Due to this feature, different parts of the drive will maintain a constant speed ratio or. Rubber synchronous belt with htd® tooth profile the curvilinear powergrip® htd® tooth geometry eliminates stress concentration at tooth roots and allows higher power capacity and longer life Powergrip® htd® 8m, 14m and 20m belts are used in high performance drives in the machine tool, paper and textile industries where durability and low maintenance are required. Gates powergrip™ gt4™ synchronous belts are still leading the market after 50 years with superior performance, better chemical resistance, and higher power.

This engineering section provides general engineering information for synchronous belts and sprockets (or pulleys) which are useful in general drive design work

Where we refer to sprockets (for powergrip® gt®2 belts), you can substitute pulleys for powergrip timing belts If you need additional information, contact gates power transmission product application. This new, technically advanced belt covers the widest range of industrial applications The powergrip® gt3 synchronous belt transmits up to 30% more power than previous generation belts (powergrip® gt2)

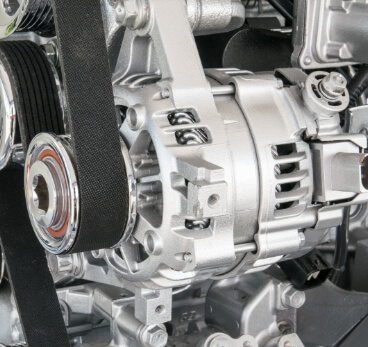

This entire belt range is suited both for new drive designs ans for replacements on existing drives without any adaptation of the system. Built to keep your operations running, save energy and deliver proven performance in demanding industrial environments Super arc belts for live roller conveyor drives engineered to provide the right amount of slip, grip, and. Shown here is a bucket elevator from feeco international that uses an electric motor through a belt drive with twin v belts for operation.

Continental's polyurethane (pu) synchronous belts combine high performance with exceptional durability, making them the ideal solution for a wide range of industrial applications

The first synchronous belts utilized trapezoidal teeth, which were derived from spur gears and offered precise positioning These belts quickly became standard in various applications, including machine tools, textile machinery, home appliances, and camshaft drives in engines. Study with quizlet and memorize flashcards containing terms like types of synchronous / positive drive belts, advantages of timing belts, difference between timing belt and v belts and more. Learn how to calculate and select synchronous belts and pulleys

From pitch and tooth profile to material and application, get expert guidance on optimizing your power transmission system. Why choose megadyne for synchronous belts many industrial systems use synchronous belts to power electric motors and other driven equipment A modern alternative to traditional belts, the positive engagement that powers these belts heightens power and minimizes the need for maintenance. To determine whether or not a synchronous belt could improve your belt drive system, consider the following top five benefits.