Precision Reveal: Why A Digital Key Chart Is Now Mandatory For Every Cnc Bench Dhr Linkge Mndtory Services Fusion Werindi

Cnc machining is a pillar of modern manufacturing, renowned for its unmatched precision and efficiency in producing complex components Here is a list of top 10 best cnc machine manufacturers and brands including mazak, trumpf, dmg mori, mag, haas, stylecnc, amada, okuma, makino, emag, hardinge. However, the true effectiveness of cnc technology hinges on stringent quality control and inspection processes to ensure that every part adheres to exact specifications.

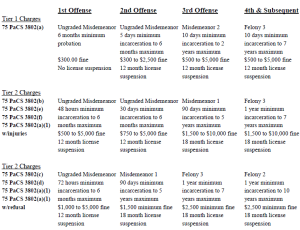

PA DUI Mandatory Minimum Sentencing Chart | Jason Dunkle Law

A precision machine shop specializes in creating highly accurate and intricate components, often with the use of advanced cnc machining equipment. We would like to show you a description here but the site won't allow us. The automotive industry relies on precision for mass production, where consistency across thousands of parts is essential

Key factors influencing cnc machining accuracy several variables impact the precision of cnc machining, from mechanical design to environmental conditions.

In the world of cnc machining, precision is the key to success Every millimeter counts when creating intricate and complex parts To achieve the highest level of precision, cnc machines rely on various measuring instruments These instruments play a crucial role in ensuring the accuracy of the machining process

In this blog post, we will delve into the world of measuring instruments in cnc. Reliability requires accuracy, precision, and the ability of the cnc machining shop that manufactures the parts to maintain tight tolerances When deciding which machining shop to use to process key components, it is important to ask two questions What is the accuracy of cnc milling, and what is the commitment of the machining shop to provide.

This article provides a basic introduction to cnc accuracy, precision, and tolerance to help readers better understand the important standards in the manufacturing process.

Machining tolerances play a crucial role in ensuring the accuracy and precision of the final machined parts Understanding and adhering to specific tolerance requirements is essential to meet the desired design. A simplified explanation of these terms would be Accuracy is achieving the correct position

Repeatability is achieving it every time A common way of defining these terms graphically is by comparison with a target practice chart, where you attempt to shoot at the centre. Discover key steps in cnc machining quality control Key benefits of smart bench essential plus include

Minimized measurement errors and precise results

Powered by keysight truevolt technology, the new solutions reduce errors from real world factors, delivering improved insights Diligence, precision, and innovative strategies are key to achieving this balance Cnc quality assurance is central to every component meeting and exceeding strict criteria and customer requirements. Every g code command sorted by how often they are used and organized by code type to make learning g code quick and simple.

With its own internal gauge wheel, reveal precisely controls the depth of the cleaning tines to create a consistently clean and ideal seeding environment for even emergence… Explore the essential distinctions between cad and cam with our breakdown of the 7 key differences every cnc enthusiast must understand. Importance of pdf downloads for cnc machine parts:\ why are pdf downloads crucial for cnc machine parts Here, we highlight the benefits of having a pdf parts catalog readily available

We discuss the convenience of offline access, easy searchability, and the ability to print or bookmark important sections for quick reference.

One key aspect that ensures the accuracy and smooth operation of cnc machines is the machine coordinate system In this blog post, we will dive deep into understanding machine coordinate systems in cnc, exploring their importance, different types, and how they work to enhance manufacturing processes. Precision snug fit bench dogs for festool mft/3, walko or other 20mm hole grid tables All dogs are machined to 0.001 tolerance to insure there will be no issues when using them to setup for 90 or 45 degrees angle cuts on your grid drilled table

All our 20mm bench dogs come with a strong form rolled m8 thread. Molded and custom cnc tool holders keep cutting tools, drills, and other essential equipment safely stored while allowing for easy retrieval. From the aerospace industry to medical devices, quality control in cnc machining is essential to ensure that every component meets the strict tolerances, specifications, and standards required by these industries. Precision setup, adept programming and a keen eye for quality control are at the heart of cnc machinist skills.