Industrial Techs Debate 5 3/8 To Mm Tolerances In Large Pumping Units Smi Sprg Lerances Royal Coil C

This blog explores why flange tolerances matter, what types exist, and how maintaining tight tolerances contributes to industrial systems' safety, efficiency, and cost savings. Dimensional tolerance refers to the maximum allowable deviation from the. Linear tolerances angular and rotational tolerances the section below describes the various fabrication tolerances that must be maintained on prefabricated piping assemblies in a production shop

Industrial Parts Warehouse Lift Techs - Crunchbase Company Profile

Internal criteria for misalignment are defined in section. The tolerance of the reamer diameter directly affects the size precision of the processed hole, the manufacturing cost of the reamer, and its service life Standards, practices, and control in any industrial piping system—whether in oil refineries, chemical plants, or power stations—the term tolerance holds critical importance.

Learn essential pipe fabrication tolerances per asme b31.3 standards

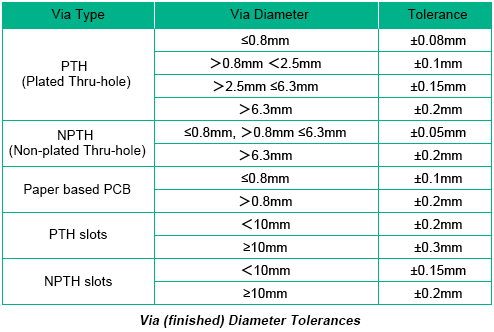

Covers linear tolerances, flange alignment, bend specifications, and quality control for piping systems fabrication. Flange dimensional tolerances this table displays flange dimensional tolerances by inside, outside, and contact diameter, thickness, and drilling tolerances for bolt holes diameter and spacing These standard flange dimensional tolerances are ideal when other specifications aren't used. Tolerance management for precision manufacturing is vital to ensure proper fit between parts and function correctly, especially when components are produced in different locations or by different suppliers

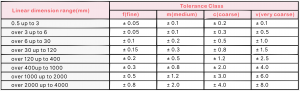

Tolerance standards allow manufacturers to control the allowable variation in part dimensions, ensuring reliable fits, proper assembly, and optimal performance across industries such as. Geometric tolerances, limits fits charts, mechanical tolerances tables and calculators Figure 15.5 presents a collection of the most common manufacturing processes and the tolerances commonly associated with each of them As explained in the legend, the shaded portions of the bars represent the average application of these processes and mean virtually any manufacturing shop should be able to achieve these tolerances.

Learn what tolerances in precision engineering are, why they matter, and how to manage them to improve manufacturing accuracy and product performance.

This article will explore the key tolerance standards used in subtractive manufacturing, specifically iso 2768, iso 286 and gd&t. Slip fit & press fit guide Understand tolerance chart fits, interference fit, slip fit, shaft alignment, and ansi standards. The geometry of the maximizer ii unit contributes to reduced torsional loads on the gearbox, which can enable the.

Wall thickness tolerances (drawn over mandrel, erw round mechanical steel tubing) Compliance with astm a519 tolerances within the astm a519 standard is a table of tolerances for hot rolled seamless tubing It lists tubing od and wall thickness (wt) Astm's tolerancing methodology is consistent with the nature of tube manufacturing.

Understand machining tolerances and their role in precision engineering

Get insights on standards, factors affecting tolerances, and best practices. Learn how to select the right industrial pump and pump size for your application. Please enable javascript to view the page content Milwaukee tool 32pc metric & 28pc sae 3/8″ drive chrome packout socket sets $ 269.99 original price was

$ 229.99 current price is M18™ packout™ six bay rapid charger $ 339.99 original price was $ 249.99 current price is Discover a wide range of industrial and commercial products with exceptional service and fast delivery from global industrial.

General tolerances, also known as default tolerances, title block tolerances, or unless otherwise specified (uos) tolerances, are standard tolerances for dimensional variation applied when specific tolerances aren't explicitly stated on an engineering drawing

These tolerances provide a default level of precision, establishing acceptable ranges for part dimensions without requiring. 1/64 1/32 3/64 1/16 5/64 3/32 7/64 1/8 9/64 5/32 11/64 3/16 13/64 7/32 15/64 1/4 17/64 9/32 19/64 5/16 21/64 11/32 23/64 3/8 25/64 13/32 27/64 7/16 29/64 15/32 31/64 1/2 Study with quizlet and memorize flashcards containing terms like which water source typically contains many millions of gallons (liters) of water and may be found on large commercial or industrial properties A.cistern b.ground reservoir c.private water storage tank d.agricultural irrigation system, in most circumstances, maximum lift is approximately

In mechanical manufacturing, determining the reamer diameter tolerance based on the size precision of the hole to be processed is common