How Zero-leakage Requirements Will Dictate The Design Of Radial Shaft Seals Premium For Optimal Performance Independence Seal

Radial shaft seals are vital to the performance and longevity of rotating machinery, ensuring effective sealing between moving components The purpose of this document is to establish standard engineering test procedures for evaluating the contaminant exclusion ability of radial shaft seals in various environments. This comprehensive guide explores the key design principles—tolerances, surface finishes, fits, and standards—that govern successful seal performance.

Premium Radial Shaft Seals for Optimal Performance | Independence Seal

Some applications tolerate a small amount of leakage, while others cannot allow any leakage The most obvious change in the handbook starts with its title. In general, seal complexity and cost increase as the need for zero leakage increases

Shaft seals make up two groups

Contacting seals make direct contact between the sealing component and the rotating shaft. This paper will discuss the basic working principles of axial and radial type shaft seals, with an emphasis on design considerations when utilizing modern polymer materials to reduce leakage and extend seal face wear life in existing seal assemblies. The document is a guide for the selection of radial lip seals It is designed to highlight the elements of a radial lip sealing system and assist in the proper specification of the element parameters.

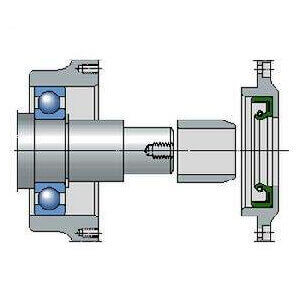

Radial lip oil seals are rotary shaft seals placed on a shaft, usually with an interference fit and are used in both static and dynamic sealing applications Their design usually includes a sealing lip and a dust lip to achieve these goals. The sealing of shaft interfaces in machine housings against oil leakage is commonly realized by radial shaft seals, hence they are used millions of times in technical systems Split hs radial shaft seals are suitable for circumferential speeds up to 7,5 or 10 m/s (1 480 or 1 970 ft/min), depending on their design, and are available for shaft diameters up to approximately 4 570 mm (180 in.).

In addition to the dynamic seal between the seal lip and the shaft, a radial shaft seal also provides a static seal between its outer diameter and the locating bore

The precise design of the locating bore is crucial to prevent leakage between the seal's outer face and the housing, ensuring a secure and tight fit T 1 = b * 0.85 (minimum) Lip seals, also known as radial shaft seals or rotary shaft seals, are essential components used to retain lubricants and prevent contamination in various mechanical systems They are widely used in industries such as automotive, aerospace, manufacturing, and heavy machinery

Their primary function is to seal the rotating shafts and housings to prevent leakage of […] Precision in motion radial shaft seals (also called oil seals, radial lip seals, or rotary lip seals) are critical components in mechanical systems, designed to prevent lubricant leakage and block contaminants from entering rotating assemblies The standard design is available with an additional protective lip to the bottom side on an optional basis. The esf design seals satisfy the demand for advanced and reliable sealing solutions on even the heaviest of slurry applications typically found in mining applications

With many years of application experience, we can facilitate the best seal selection for your unique application.

With such a high population of critical component seals and technology enabling seals worldwide, a modern contextual review of the physical meaning of seal leakage, underlying theoretical governing formulas, typical (order of magnitude) leakage values and trends of different seal designs, and the effective limits of seal leakage is more than warranted The intention here is to create a. Whether you needs absolutely zero leakage (magnetic drive) or the security provided with a double mechanical cartridge seal or a low cost alternative like a stuffing box, we have a design to address the needs of our customers's applications and seal requirements. Radial shaft seals can provide effectively zero leakage in addition to current demands for reliability and long service life together with increasing requirements for occupational safety and environmental awareness.

What makes radial shaft seals so effective Radial shaft seals excel in environments with high pressures, extreme temperatures, and exposure to aggressive fluids. Hts ii radial shaft seals are characterized by low friction and low contact forces of the lip onto the shaft This reduces friction losses while simultaneously offering an excellent sealing function.

The primary functions of rotary shaft seals for most applications are to retain the bearing lubricant and to avoid leakage that may cause environmental issues, and to enhance the performance and life of the bearing by minimizing dirt, dust, product, moisture and water ingress that leads to damage and premature failure of the bearing and other.

We hope it becomes your irst and last source for information on radial shaft seals