How Future Power Tools Will Integrate Miniature High-strength Shaft Lock Circuit Breaker Electrical Safety Out Min Vicedeal

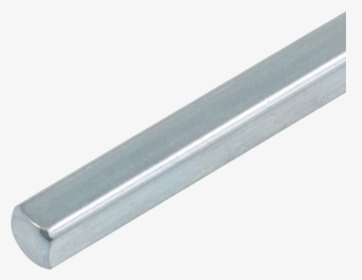

Over the past decade, the landscape of miniature power tool kits has undergone significant transformation. We offer a variety of normal and high strength gears, available in multiple shapes and sizes. High strength shaft hardware functions similarly to standard ⅛ shaft hardware, just on a larger scale

1:12 Miniature Door Lock, Dollhouse Door Lock With Key, Mini Door Lock

Use the high strength shaft bearing to allow shafts to turn smoothly, the high strength shaft spacer kit to position objects on a shaft while reducing friction. Gears are one of the primary sources of power transmission The future of power tools is all about intelligent performance

Smart technology is revolutionizing professional power tools, offering users unprecedented control and insight into their equipment

These new 2026 tools show just how far hilti has come They're building better systems, faster, safer, and more connected than ever Below, i've included a few quick videos for each category to give you a closer look. Based on tool manufacturer innovations, here's what we think will be the big changes in the future of power tools

Innovations in battery technology will enable longer usage times Smart tools with iot integration will enhance efficiency and user experience The rise of augmented reality tools will transform how users interact with power tools. Beyond just the convenience, cordless power tools represent a significant leap towards greater worksite mobility and safety

Without the need to be secure to power outlets, users can take their tools to more remote or unpowered sites, broadening the scope of projects that can be tackled.

Rather than keying a separate gear or pulley onto a shaft, manufacturers are increasingly machining splines, pinions, and flanges directly into the shaft material This reduces part count, assembly time, and potential failure points. Discover the latest power tool trends shaping 2025 Click to explore the future of power tools now!

Shaft collars lock to drive shafts, keeping wheels and gears from sliding along the shaft Collars fit around drive shafts and can be fastened in place using a hex or star drive set screw Clamping shaft collars use a standard hex or star drive v5 screw and nut to maintain a tight lock without scratching or damaging the shaft Rubber shaft collars easily slide onto shafts

High strength shafts, as the name implies, are much more durable than low strength shafts, being able to be used in much higher torque situations as such

For instance, high strength shafts are ideal for linking both sides of a lift through a common shaft. Complete guide to shaft keys covering the motor key types, dimension formulas, strength calculations, material selection, and practical case studies for reliable torque transmission. We would like to show you a description here but the site won't allow us. High strength stud locking adhesive for all types of metal

See that bigger hole inside a vex v5 motor That's for high strength shafts, which is convenient for a hs shaft, that is not what we're doing with motors in this build This hole makes shafts likelier to slide out of the motor Radial shaft seal design ensures reliable performance in precision machinery.

High strength shaft collars are designed to fit onto high strength shafts

The direct transfer of motor power enables precise tool control Additionally, they reduce user fatigue through ergonomic handling and lower vibration transfer. Today, let's dive deep into the top ten bearing markets with the most promising future prospects Let's see where the gold mines shine the brightest and which fields are most worth exploring.