The Tapered Roller Logic Found Inside Modern Browning Bearings Engineering Data Rbc Incorporated

A tapered roller bearing is a unit that consists of both tapered raceways (inner and outer rings), and tapered rollers Of america catalog including ball bearings,tapered roller bearings,cylindrical roller bearings,needle roller bearings,spherical roller bearings,mounted ball units,mounted roller units,parts & accessories The construction is intended for combination loads, such as dual acting axial and radial loads.

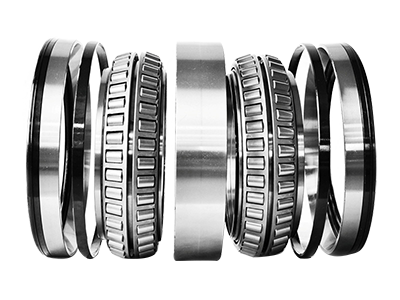

Four Row Tapered Roller Bearings | WZZZ

Taper roller bearings have tapered inner and outer ring raceways between which the tapered rollers are arranged Browse all categories in the ntn bearing corp If extended, the tapered surface would converge towards a single point on the bearing axis

This means the rolling conditions are optimum.

Figure 1.1 shows the main components of a trb that are the cup, cone, tapered rolling elements, bearing cage, and lubricant (oil or grease) The rolling elements are kept in the bearing cage that locates between the cone (ir called inner race) and cup (or called outer race). The comprehensive exploration of tapered roller bearings has highlighted their key components, including the inner and outer rings, tapered rollers, and cage, which together contribute to superior performance and durability. Tapered roller bearings feature a cup and cone assembly

The cup is comprised of the outer ring and the cone assembly consists of inner ring, rollers, and cage This bearing construction accommodates combined loads and provides low friction during operation. Discover the versatile world of tapered roller bearings, with tapered cup, cone, and aligned design Efficiently manage axial and radial forces.

For tapered roller bearings, which are often subjected to extreme stress, the choice of material and the manufacturing process are not just details—they are fundamental to the bearing's function and lifespan.

Tapered roller bearings consist of four basic components An inner ring, an outer ring, tapered rollers, and a cage In general, the inner and outer raceways and rollers are loaded, while the cage separates and stabilizes the rollers. Unlike standard ball bearings, bearing roller tapered systems are designed to manage complex forces with precision

In this article, we'll break down how they work, where they shine, and what makes them a cornerstone of industrial and mechanical design The e920 series has set screw locking collars for easy installation and a contact face riding seal to provide a good balance between contaminant entry, grease retention, and friction. These bearings are capable of supporting high radial and axial loads and are designed to handle both thrust and radial forces simultaneously In this blog post, we will provide an overview of tapered roller bearings, including their construction, operation, and applications.

These bearings have conical rollers and raceways designed to handle large radial and axial loads

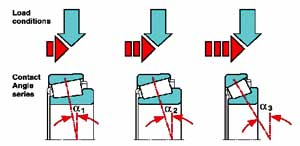

They are often found in automotive wheel hubs, gearboxes, and railway applications. Tapered roller bearings are made of tapered raceways in the inner and outer rings with conical rollers Due to the contact angle, tapered roller bearings can handle high radial and axial forces in one direction. Find efficient tapered roller bearings at dph engineering, perfect for handling radial and axial loads in automotive, industrial, and construction applications.

Types, design features, and characteristics tapered roller bearings are designed so the tapered vertex of the raceway surfaces of the inner and outer rings and rollers converge at one point on the centerline of the bearing (see fig Taper roller bearings are crucial components in a variety of mechanical applications, especially where heavy loads and rotational accuracy are critical Known for their ability to handle both radial and axial loads efficiently, taper roller bearings are widely used in automotive, industrial, and heavy machinery sectors This blog provides a detailed introduction to taper roller

Various types of bearings are used to lessen this friction force for moving mechanisms such as machines

The bearing gets its name from the fact that it bears a turning axle or shaft, but those parts used for sliding surfaces are also called bearings Bearings include rolling bearings, which use balls, or rollers called rolling elements. Tapered roller bearings in subject area Engineering tapered roller bearings are designed to support both radial and thrust loads, featuring tapered rings and rollers that resemble truncated cones

They are commonly used in applications like car hubs, where their ability to handle varying load ratios based on the contact angle is essential. A&i products abb accor accurate bearing co Acorn industrial services acron ring and specialty corp Their unique conical shape, formed by the inner and outer raceways and the roller assembly, allows for the transmission of forces in a specific direction

This makes them ideal for applications with combined loads.

Tapered roller bearings support heavy radial, axial, or thrust loads They consist of a tapered ring and cage that hold the rollers, and a cup that serves as the stationary outer ring that supports the rollers as they rotate Tapered roller bearings can tolerate shock loads and are commonly used in construction, mining, and farming equipment.