The Internal Gear Geometry Within A High-efficiency Reduction Gearbox Wht Is Box? How Does Speed Reducer Wo

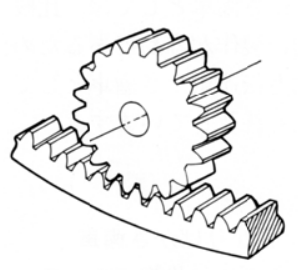

5.3 internal gear with small differences in numbers of teeth in the meshing of an internal gear and an external gear, if the difference in numbers of teeth of two gears is quite small, a profile shifted gear could prevent the interference. They have specific geometric features and parameters that determine their function and performance. This architecture is called nested since it involves stages with internal and external gears arranged one inside the other.

KZA series triple reduction hollow shaft gearbox - Helical Gearmotors

Knowing how to calculate gear reduction is a must for engineers and technicians designing reliable power transmission systems Internal gear is a type of gear where the teeth are cut on the inside surface of the gear, rather than the outside like in external gears Whether you're developing an industrial gearbox, a robotic arm, or a conveyor drive, proper gear reduction provides the right balance of torque and speed while maintaining gearbox efficiency

Throughout this guide, we break down the whole process — from basic.

The calculation of gear dimensions page covers the procedure for determining the sizes of gears The size of a gear is defined by the module etc. The results show that helical gears exhibit a higher efficiency than internal gears due to their spiral tooth profile, which reduces the frictional losses between teeth Noise reduction is an essential aspect of gear design, particularly in applications where quiet operation is crucial.

Understanding the technical definitions and design principles of internal gears is essential for anyone working with mechanical systems. However significant effort, judgement and expertise is required in designing the whole system including the gears, shafts , bearings, gearbox, lubrication Unlock precision and efficiency with our ultimate guide to reduction gears This allows the engineer to choose the compromise that best fits his need

Several studies have reported on the optimization of gear design aimed at reducing power loss [4], weight of the gearbox [5], mesh excitation [6, 7] and the different issues encountered along the power drive line like optimal gear ratio and position of shaft axes [8].

While internal gears are ideal for applications for high power transmission within small overall dimensions, there are design constraints that must be addressed in order to achieve the advantages that internal gears offer. Increasing the gear ratio (gr) while decreasing the gearbox dimension is a contradiction that mechanical designers are challenged to solve Power losses in gear systems are associated primarily with tooth friction and lubrication churning losses The tip geometry of a pinion type cutter which determines the fillet of internal gear tooth can be sharp or rounded

In this study, the design of internal gears were investigated by using a. Advanced epicyclic gear design ensures high torque, compactness, and efficiency Explore materials, precision, and thermal management for top performance. When it comes to gearing systems, internal gears can become very useful in reduction systems when used correctly

If you've ever found yourself puzzled by terms like internal diameter, pitch diameter, or internal spur gears, you're not alone

These are key components that determine how gears mesh and transfer power effectively This approach is certainly more manufacturing friendly than the dgd, although it compromises some gear performance (for example, bending stress reduction) In the second case for the gear design with the asymmetric teeth, the dgd defines the optimized gear geometry the similar way only using the different base circle for each tooth flank. Gears are used to transmit torque and rotational motion between shafts

Their geometry is critical for the efficiency, precision, and durability of the gearbox Classification of gears gears are primarily classified into the following types Include spur gears and helical gears Include straight and spiral bevel.

Types and mechanisms of gear reducers with parallel axes the gear reducers with parallel axes use spur gears, helical gears, or herringbone gears

Their input and output shafts are parallel.