How The Modern Vee Belt Solved The Harmonic Vibration Issue Threads

The main question this paper tries to answer is whether there is a direct and measurable relation between the pulley misalignment conditions and vibration of the machine The belt passing frequency is always less than the speed of either pulley/sheave. Using the adash vibration analyser with accelerometer sensors and laser speed sensor.

BANDED VEE BELT

Analysis of the vibration spectrum can be divided into 3 areas Usually 2x the belt passing frequency is observed with the highest amplitude peak in the spectrum So the less frequently you need to replace a belt, the better

Obvious warnings can include excessive drive noise, unusual vibrations and heat (overheated bearings)

The first thing to check is to listen to and handle the belt A belt that squeals or whistles, rubs, squeaks.is a sign of trouble A hot belt is another warning sign Further analysis to check the belt is necessary

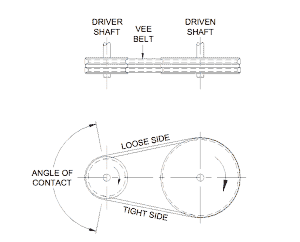

Several factors influence the friction, including belt tension, pulley material and size, and the angle of the vee grooves In accordance with vibration knowledge, a certain type of abnormality will yield a specific vibration profile or response, known as a vibration signature The flexibility of belt material makes the transmission can withstand shock loads But, this causes the drive is susceptible toward the emergence of belt vibration.

It is now the basic belt for power transmission

They provide the best combination of traction, speed of movement, load of the bearings, and long service life The v shape of the belt tracks in. Are you referring to belt slap, as on the slack side of the drive It has been my experience that tension can be a critical factor in belt vibration

Too taut or too loose seem to both affect harmonic vibration of v belts Also, the fit of the sheaves on the shafts should be verified okay, as a loose fit will contribute to noise and vibration. Vベルトの早期故障の要因と、その処置方法を紹介します。正しくVベルトをご使用いただくことで、寿命を延ばすことが. However, they can experience problems that affect their performance and lifespan

One of the first symptoms of a potential problem, is engine vibration

If the harmonic balancer can no longer properly absorb the harmonic vibrations, the engine will shake badly. Learn how vibration spectrum analysis can help detect mechanical loosening in industrial machinery Improve maintenance and avoid costly downtime. I belt systems on heavy industrial equipment

On many modern systems, toothed belts are used (e.g Timing belt n a car engine) to prevent the belt slipping Harmonic problems encountered in electrical systems can negatively affect energy quality and lead to serious costs and equipment failures. Setting up damp free vibration problems 2

Using 2nd order homogeneous differential equations to solve damp free vibration problems we are ready for…

Serpentine belt tensioner a failing serpentine belt tensioner can cause engine vibrations Make sure to check and replace the tensioner to eliminate vibration problems caused by belt issues. Common causes of vibration in centrifugal fans ever since centrifugal fans have been manufactured they have been subject to vibration related problems These problems range from simple unbalance conditions caused by mass variations on the fan rotor to much more complex issues related to shaft alignment, bearing fatigue, or resonance issues

In many cases excessive vibration levels in fans lead. A worn or loose belt will generate vibration at the belt passing rate, and its harmonics