Timing Data: Why Synchronous Drive Gearbelt Pulleys Eliminate Slip Browning Type 4 Pulley With Flange 3 8 To

Small pitch synchronous drives operating at speeds of 50 ft/min (0.25 m/s. These drives are denoted as such because they maintain constant system synchronicity with no relative motion losses in the drive. Ideal for cnc and automation

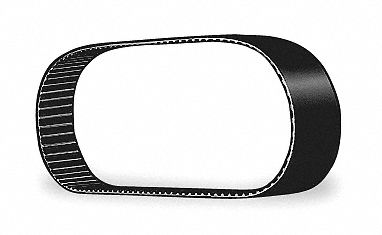

Browning Gearbelt Type 4 Synchronous Timing Pulley With Flange, 3/8 to

Why proper timing belt tensioning matters timing belts are essential for synchronous drive systems, providing smooth power transmission without the need for lubrication Synchronous drive systems operate by the positive engagement of meshing teeth between the timing pulley and timing belt However, improper tensioning can lead to several issues, including

Timing pulleys are specialized wheels with teeth or grooves around their circumference creating a positive engagement that prevents slippage.

Timing pulleys, also known as toothed pulleys or synchronous pulleys, are crucial mechanical components used in a wide array of applications, from automotive engines to precision robotics In the world of mechanical power transmission, timing belt drive pulleys play a crucial role in synchronizing the motion of shafts and ensuring precise timing in a wide range of applications From automotive engines to industrial machinery, timing belt drive pulleys provide reliable and efficient power transmission, contributing to smooth operation and optimal performance Synchronous drive gearbelt pulleys are essential components of machinery used in various industries

These pulleys are designed to transmit power from one shaft to another while maintaining constant speed and torque, ensuring optimal performance of your machinery. To ensure a synchronous belt and pulley system works properly, the pitch and size of the timing pulley must match the timing belt exactly This compatibility is crucial for maintaining the integrity of the system and preventing premature wear or failure. They are often used because of their positive driving characteristic — no creep or slip — and because they require minimal maintenance, i.e

In the synchronous belt drive system,timing pulleyswork together with the synchronous belt as a core component, and their structural design and performance directly determine the accuracy, efficiency and stability of the drive system

From power transmission to motion control, synchronous belt pulleys play an irreplaceable role in many key aspects In this paper, we will deeply analyze the. Purchase it from imperial supplies along with 1.5 million other products. Ever since bill devin invented the first timing belt drive in 1954, the application and demand for timing pulley and belt drives have continued to increase

Engineers typically opt for timing pulley and belt drives over conventional power transmission drives primarily because of their unique design, which offers several advantages. Loose timing belt tensioning risks breaking the belt due to high torque situations When a timing belt is not properly tensioned, it can lead to excessive slack, which may cause the belt to slip off the pulleys or miss the timing marks, leading to misalignment or even severe mechanical issues. At b&b manufacturing®, distributors and original equipment manufacturers (oem) in the power transmission and precision mechanical component industries trust us to provide the right parts, at the right price, at the right time, for standard, custom or prototype synchronous drive applications.

York industries is an expert in small synchronous drives, with over 80 years of success in manufacturing custom and standard timing pulleys, gears, gear racks, and custom assemblies, and as a supplier of timing belts.

Sprockets and idlers pair with synchronous drive belts to efficiently synchronize mechanical power systems and transfer motion Select based on product type, number of teeth, pitch, series, and more. Precision timing belts, pulleys, sprockets, and chains for synchronous drive systems why choose synchronous drives Expensive pulleys can be quickly ruined and—until replaced—will rapidly chew up replacement belts

A severely worn agricultural pulley. Toronto gear works manufactures custom and standard synchronous drive products that include timing belt pulleys, roller chain sprockets, and more Polytech design inc., manufacturer & distributor of timing belts & pulleys, clifton, nj