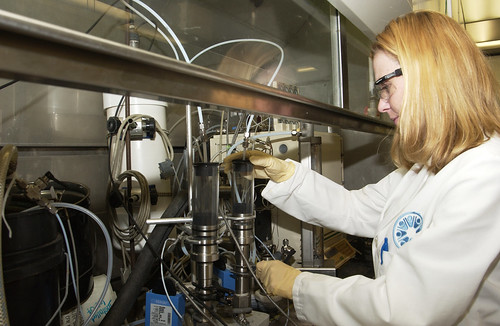

The Engineering Strategy Of Uniform Pressure Provided By A Threaded Clamp Collar รูปภาพ เทคโนโลยี อุปกรณ์ อุตสาหกรรม เครื่องจักร แขน วิศวกรรม

Threaded clamp collars are designed for threaded shafts and provide a relatively high axial loading force Also, check if the collar can handle your maximum rotational speed without loosening or producing imbalance. Like threaded clamp collars, these devices can be repositioned as necessary.

1366x768px | free download | HD wallpaper: indonesia, surakarta

(a) side view illustrating the clamp's lever mechanism, where the applied force generates clamping pressure A clamp collar typically offers stronger and more consistent holding power than a single set screw (b) isometric view highlighting the clamp's support surface on the profile flange, showing dimensions (k) and (w) that ensure uniform distribution of clamping pressure across the flange.

Threaded fasteners are one of the most commonly used connection methods for mechanical structures

Its primary function is to generate appropriate clamping forces and fasten the connected parts An inappropriate preload can cause loosening, fatigue fracture, and other problems This will affect the safety and reliability of mechanical equipment The precise control of the preload has become a.

Conclusion in conclusion, determining the optimal clamp pressure distribution is crucial for accurate calculation of clamping force There are several ways of securing parts and components to each other, e.g Gluing, riveting, welding and soldering The advantages of this method are the simplicity of design and assembly, easy.

Instead of marring the shaft with a set screw, clamp style collars utilize compressive forces to lock the collar onto the shaft

For this reason, clamp style collars are easily for removed, indefinitely adjustable, and work well on virtually any shaft The design includes a collar with a split on one side The cap screw, used to tighten the collar, runs through the side of the collar itself and doesn't come into contact with the shaft Tightening the screw creates pressure all around the shaft, providing clamping force through 360°, which also creates more precise clamp locating.

Threaded and smooth bores are also features for consideration when selecting a collar Threaded bores provide positive engagement through the threads, promoting more holding force than smooth bore shaft collars Installation shaft collars will either be installed axially or radially, depending on their design. Tightening the clamp screwpulls the collar onto the shaft, creating anearly uniform ring of forces holding itto the shaft

Setscrew collars, on the other hand, rely on forces at only two.

This design facilitates straightforward installation and removal without the need to slide the collar along the shaft. Threaded bore shaft collars threaded bore shaft collars threaded shaft collars have unf, unc & acme thread options that won't damage threaded shafts, are easily adjustable and can be used for fine positioning They clamp in place to provide positive location This page provides an overview of threaded shaft collars, including a product definition, key features, and common applications.

Friction in threaded fastener joint understanding friction in threaded fastener during tightening is the key to achieving desired clamp force. They are suitable for a wide range of shaft materials and provide a more uniform distribution of forces, resulting in increased holding power compared to set screw collars. Catalog including part number,threaded bore size,material,type,outside diameter,width,cad Friction (29 of 47) the clamp

1 (part 2/2) michel van biezen 1.11m subscribers subscribed

The slip torque is then fslip times the shaft radius The total contact force is exactly the same for your single piece clamp collar with one screw because tensile stress in the collar opposite the single screw provides the same tension as would a second screw The analysis gets tricky if the collar is thick and fits loose. However, as the clamp is comprised of two halves, it allows for greater flexibility in terms of installation.

Our facilities are compliant with all relevant industry standards, including asa, asme, ansi b18.3, iso 9001:2015, reach, and rohs.