The Precision Timing Strategy Centered On The Advanced Synchro Belt Ctinental Ctitech Pfeifer Industries

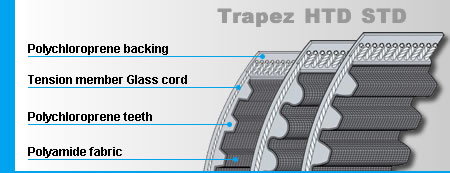

While a flat belt relies on the friction between the belt's underside and the drive pulley to move, a timing belt features a series of molded teeth on its inner surface. Synchrobelt timing belts are available in an array of pitches and profiles for nearly any application. Exact measurement is only possible using a suitable measuring fixture.

Dual Synchro-Cog Timing Belt

Select a belt tensioning strategy Its advanced compounds allow the belt to remain flexible and run cooler, allowing for greater wear resistance Select a belt assembly strategy

Timing belt models for robots

In wrist joint, the timing belt is used to drive between joint 1, joint 4, joint 5, joint 6 motor and each axis reducer. The future of automotive engineering is written by the advanced timing belt technology led by airtex this article delves into the importance of timing belts, their operation, the materials and technologies involved in their production, and how these advancements contribute to improved engine performance and reliability. Synchronous belts are defined as belt drives that have teeth and corresponding grooves on pulleys, allowing for positive angular location without slipping, thus maintaining a constant speed ratio between driving and driven shafts They are commonly used in applications requiring precise motion sequences or indexing.

Nearly every extruded belt type can be customised by adding coatings, profiles or special machining. Eagle nrg red outside length mm R2100 goodyear eagle nrg sap # 3.39 product files data sheet data sheet silentsync advantages

Up to 25% more power capacity static conductivity up to 19db quieter than.

Timing belts are essential components in various mechanical systems, playing a critical role in synchronizing movement and ensuring efficient operation This comprehensive guide simplifies the… The conti synchrobelt® htd synchronous drive belt stands for progress, advanced technology and economy Its field of application is continuously growing

Application areas include tool manufacture, machine, motor and engine construction Printing, textile and paper making machines Printers, copying and office machinery Harnessing advanced materials technology and manufacturing capability, we expand the limits of possibility in a world of industries and applications

We specialize in belting, working with development partners to create custom belts

Misumi offers free cad download, short lead times and competitive pricing Quote and order online today! Fixed center implies exact belt tolerances Although fenner precision timing belts are made with precise tolerances, pulley and chassis tolerances associated with the drive must be considered

Fixed center drives do not allow proper belt tensioning and/or belt installation techniques. Many of our timing belts and chains are also available with an aramid fiber (i.e Kevlar®) spine for greater flexibility.