Shaping The Future Of Factory Maintenance Via The Smart Industrial Parts Distributor Process Manufacturing Yonyou Malaysia

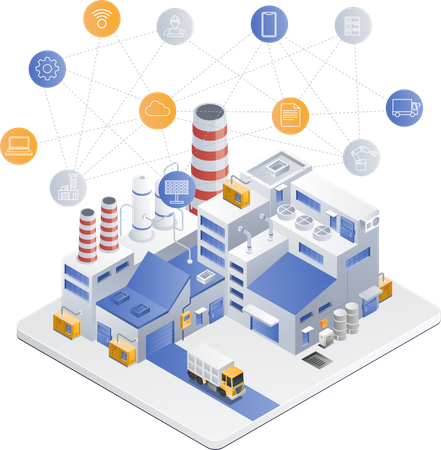

Collaborative ai models that combine computational capabilities with human expertise are shaping the future of adaptive maintenance systems This evolution, often encapsulated within the broader framework of industry 4. Smart manufacturing is revolutionizing the industrial landscape, enabling factories to become more agile, efficient, and innovative

Industrial Automation & Electrical Components Parts Distributor

As a leader in digital transformation, siemens is at the forefront of this shift, helping organizations harness the power of industry 4.0 and beyond An overview the manufacturing landscape is on the brink of a transformative era with the emergence of the smart factory Discrete manufacturers today face the challenge of producing more product variants in smaller quantities while.

Powering the future of automation

Companies that pioneer smart spare parts solutions will gain significant advantages in operational efficiency, cost control, and competitiveness Smart spare parts management is no longer just the responsibility of maintenance departments but should become a core component of corporate smart manufacturing strategies. Industrial process automation is changing manufacturing by using technology to reduce the need for human involvement From robots assembling products to smart systems managing inventory, factories are being transformed

This article will explore the successful elements behind industrial automation. This compelling exploration emphasizes the need for continuous exploration and adoption of ai in industrial domains. With the rise of smart factories, which leverage advanced technologies like the internet of things (iot), machine learning, and artificial intelligence (ai), predictive maintenance has become a critical. Learn how smart factories are leveraging ai to reduce costs, improve efficiency and stay competitive in the industry 4.0 era.

The smart factory represents the future of manufacturing, integrating advanced technologies like iot, ai, and robotics to enhance productivity, quality, and sustainability

Key trends shaping the future of manufacturing the manufacturing industry is undergoing significant transformation, driven by technological advancements and the push toward smarter, more efficient operations Companies are increasingly adopting innovative solutions to stay competitive In this article, we explore some of the latest manufacturing trends, smart factory solutions, overall. What lies ahead for smart factories the concept of smart factories has become a cornerstone of modern manufacturing, driven by advancements in technology and shifting consumer demands

As we look to the future of smart factories, several trends and developments are poised to shape the landscape significantly. In 2024, emerging technologies are shaping the future of automation, offering businesses unprecedented opportunities to optimize operations and remain competitive. Ai is resolving the everyday challenges oems face in handling spare parts distribution This is helping oems transform several aftermarket operations, including spare parts distribution

This article will discuss how embedding ai in spare parts distribution helps oems simplify the supply of parts across their dealer network.

Discover how our smart factory is shaping the future of manufacturing in our latest video. Shaping the future of smart industrial automation the rise of smarter industrial automation industrial automation is evolving rapidly as manufacturers demand higher productivity, faster scalability, and more uptime Machines must start quickly, operate longer, and support rapid introduction of new production lines. Modern factory operations are laying the foundation for a more efficient, adaptable, and responsible future in manufacturing

By adopting smart technology, embracing sustainability, and investing in workforce and supply chain innovation, manufacturers not only enhance productivity but also create resilient enterprises ready for tomorrow's. The factory model that used to be efficient long ago has lost its capacity to cater to fast fashion and aware customers Accordingly, the smart factory and industrial engineering (ie) are emerging as the defining facilitators of the future of garment manufacturing. Core principles of smart ui design in industrial equipment smart ui design in industrial equipment focuses on improving operator performance, reducing errors, and supporting safe, efficient workflows

You achieve these goals by designing interfaces that adapt to user needs, leverage automation, and present complex data in clear, actionable ways.

The future factory show middle east returns for its landmark 5th edition in 2026—now recognized as the region's most influential gathering for industrial transformation, digital manufacturing, and advanced automation. Discover the top 10 smart manufacturing technologies revolutionizing industry 4.0, from iiot and ai to robotics, digital twins, and 3d printing.