The Contamination Strategy Using A Dual-material Radial Lip Seal Rdil Sel Section Downlod Scientific Digrm

The affect of this additional lip is an increase in underlip temperature ans a loss of seal life Contact us for custom solutions! Most radial shaft seals are designed to operate under a level 1 or 2 contamination environment

Radial lip seal section. | Download Scientific Diagram

This includes radial shaft seal profiles having a secondary dust lip Choose our premium radial shaft seals to prevent leaks and block contaminants in automotive, industrial, heavy equipment, agricultural, and marine applications This lip provides only minor protection and is often misused in applications.

Introduction radial shaft seals (rss) are typically used to avoid leakage of a lubricant from the lubricated interior of a machine, while allowing for the transmission of power to the outside through a rotating shaft

Their secondary function is to prevent ingress of environmental substances such as water or dirt/dust particles into the machine While water ingress would substantially inhibit. The document is a guide for the selection of radial lip seals It is designed to highlight the elements of a radial lip sealing system and assist in the proper specification of the element parameters.

This technical bulletin presents standard engineering laboratory test procedures for evaluating the contamination exclusion capability of radial lip shaft seals in various application environments. Double lip sealing rings sd protect the guide rollers against contamination from outside The sealing rings are fitted such that the seal lip faces outwards and the protective lip faces inwards. Lip seals, also known as radial shaft seals or rotary shaft seals, are essential components used to retain lubricants and prevent contamination in various mechanical systems

They are widely used in industries such as automotive, aerospace, manufacturing, and heavy machinery

Their primary function is to seal the rotating shafts and housings to prevent leakage of […] Lip seals are an important part of modern industries, where they help contain lubricants, keep contaminants at bay, and prevent leakage This guide will cover all the essential details about lip seals, from discussing their function to common types and how to install one yourself How does a lip seal function

Learn what a lip seal is, how it works, and the different lip seal types used in industries Discover the benefits, applications, and maintenance tips. Double lip seals offer numerous compelling advantages that make them an indispensable component in modern machinery and equipment First and foremost, their dual sealing action provides unmatched protection against both internal fluid leakage and external contamination, significantly reducing the risk of system failure

Lip seals, also known as radial seals, are used to seal the transition between a rotating shaft and a stationary housing component

This is accomplished by a flexible lip that closes tightly around the shaft. Rotary seals/lip seals are a vital component used in pumps, compressors, gearboxes, motors, marine applications, automotive applications and in the food and beverage and pharmaceutical industries. The effectiveness of your radial shaft seal depends on the lip type selection This is the most important design variable and will determine both the life expectancy and cost.

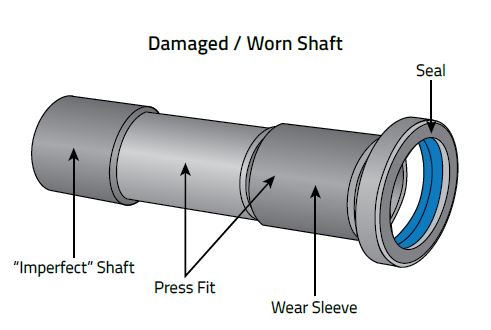

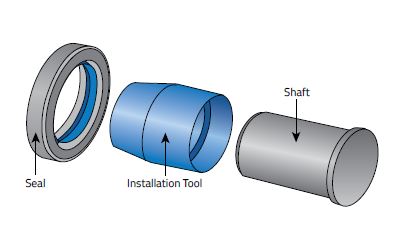

Improved chemical resistance through the entire range of elastomers Available in all elastomeric klozure® oil seal designs. Once the seal material has been selected, the next step is to consider the seal's construction In the past, a simple lip seal consisted of a leather strap on a wheel axle

Today's lip seals have multiple parts that affect how the seal performs

Engineered seal products is your source for cost effective, high quality radial shaft seals We can provide solutions for all of your sealing needs Essential guide to lip seal installation for precision in sealing technology Learn materials, applications, and best practices for optimal performance.

The usage of lip seals is very important because they can prevent the leakage adn contamination This post will talk more about the functions about lip seals and offer you some tips. Discover what lip seals are, how they work, and why they're key to preventing leaks and protecting equipment in industrial and mechanical applications. During shaft rotation, a small fluid film (~1 μm) will form between shaft and sealing lip because the shaft will drag oil in the contact /4/

The friction in the contact causes the sealing lip to deform circumferentially, creating a distortion pattern which is more pronounced on the air side end due to the asymmetric contact pressure distribution

Oil being dragged in circumferential. A lip seal, also called an oil seal or radial shaft seal, fits into a housing bore and seals radially against the shaft to prevent fluid leakage and block contaminants A new meshing algorithm is used to discretise different sealing edge surfaces and automatically generates structured hexahedral meshes of the sealing edges Epdm and silicone we manufacture our lip seal profiles using solid silicone or epdm compounds, chosen for their exceptional properties

Highly flexible and durable, silicone performs well in demanding environments without warping or deterioration, making it ideal for constant use.