The Tooling Precision Strategy And The Correct 9 16 X 18 Tap Drill Size Npt Thread Chart Infoupdate Org

The recommended drill bit size for a 9/16 tap is 33/64 inches, slightly smaller than the tap, to ensure proper thread depth and a secure fit Converting between inch and metric will help finding drills of similar size. Precision is key when working with a 9/16 tap to prevent thread stripping and ensure a strong connection between mating parts.

Acme tap drill size chart - dongear

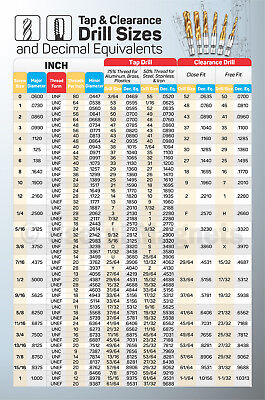

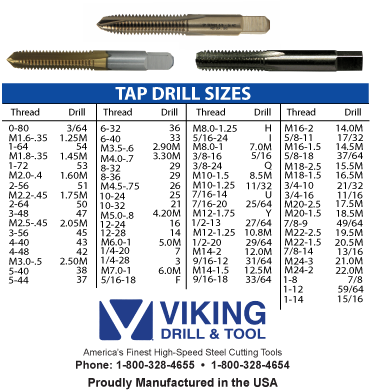

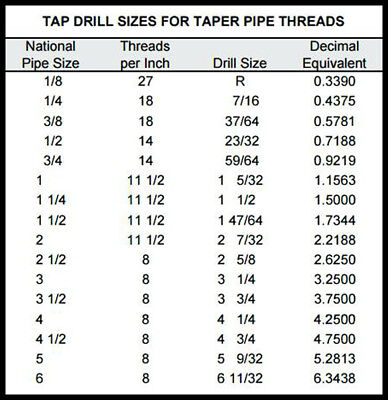

Use our tap drill charts to find the right drill size for screws or bolts and ensure perfect threading every time. The tap hole size may need to be adjusted based on your specific tolerance, material, and hardness Explore the complete tap drill size chart for accurate threading

Choose the right drill size for each tap and ensure reliable thread formation every time.

Tap drill size calculator for inch and metric threads (for cutting and forming taps) Plus formulas and charts for tap drill size. Discover the updated tap drill size chart with metric and imperial sizes Download the free printable pdf and master accurate hole sizing.

To determine the correct drill bit size for a 9/16 tap, we need to consider the thread size and the material being tapped In the world of machining and metalworking, precision is everything One essential calculation machinists and engineers regularly perform is determining the correct tap drill size for threading operations Using the wrong drill size can result in poor thread quality, stripped threads, or even damaged materials and tools

That's where our tap drill calculator comes in—a fast, reliable, and.

Discover the key to flawless tapping operations in diy projects by choosing the right drill size for a 9/16 tap This article delves into the essentials, including drill bit selection (1/2 or 27), tap depth, lubrication methods, materials, and safety precautions, ensuring accurate and durable threads Unveil expert tips like tap identification, consulting drill charts, material thickness. List of drill and tap sizes schematic of a machine tap below is a comprehensive drill and tap size chart for all drills and taps

Inch, imperial, and metric, up to 36.5 millimetres (1.44 in) in diameter. A thread tap is the precision tool that transforms a hole prepared to the correct tapping drill size into a fully functional internal thread It ensures the profile matches the required pitch, diameter, and tolerance for the application. Drilling is a process of producing a hole while tapping is a technique used to cut a thread inside a hole, so the drill bit and tapping tool are often used in sequential to fabricate cnc parts with thread holes

When it comes to the selection of drill bit sizes and tap sizes, there are standard drill and tap size chart for reference.

At penn tool co., we've curated a diverse selection of their best tools From woodworking and metalworking to manufacturing and engineering, precision twist drill offers a solution for every craftsperson. Precision in drill bit selection is crucial for achieving desired thread depth and secure connections. The tap drill size of a hole that will be cold form tapped is usually bigger than it cutting tap counterpart

(77% thread is what you want to use) a 100% thread is 3/4 qtr, or (6/8 th), of the full 60° triangle which is the maximum allowed height of a full thread, the v shape, including flats. Drill and thread cleanly using tap & drill sets for metal, wood, and plastic Shop a wide collection of durable options today at lowe's. Utilize tap drill charts to find the recommended drill size, test on scrap material before the actual project, and use lubrication for smoother drilling

From understanding thread sizes to mastering tapping techniques, ensure precision in all your diy projects with our valuable tips.

Therefore the tap drill chart is extremely important To create a thread properly, one would need a set of three taps that correspond to the same bit size Namely the bottoming, the intermediate, and the taper tap Discover the what size drill bit for a 3/8 tap, whether coarse or fine thread

Learn from personal experiences and expert tips to ensure perfect threading every time. To drill holes for these taps, you'll need a drill bit that's slightly larger than the tap's thread size. Speeds & feeds din standards thread mill cnc program generator tap drill calculator milling performance optimizer contact tech support A tap drill calculator is a tool that helps users find the proper drill bit size needed before tapping a threaded hole

This ensures optimal thread engagement and tool performance.

The recommended practice for roll taps is to drill and ream the hole The thread dimensions are formed by a combination of the tap and tap drill size This recommendation chart is a starting point