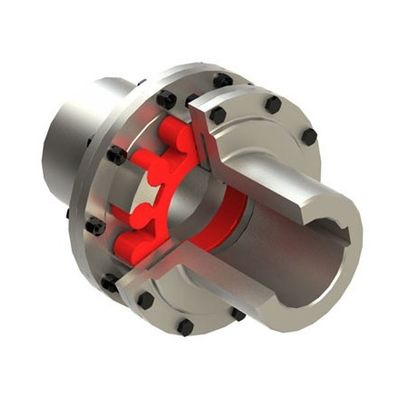

Sound Tech Debate: Is The Rubber Shaft Coupling The Quietest Option? Cgm Insert Compressor Oil Restant

Rubber coupling is an important component of machinery that transmits power from one shaft to another Durable flexible joints for oem replacements, high pressure & temperature resistant. Reducing noise from rubber coupling is important to ensure that the machine operates smoothly and efficiently.

Boston Gear XFCR38 Rubber Coupling Insert - Twin Spring Coupling

Flexible couplings reduce drivetrain noise by absorbing vibrations and misalignment, helping extend equipment lifespan and lower maintenance costs. Find drive shaft rubber parts with epdm/nbr material, ce/iso certified Flexible shaft coupling considerations flexible shaft couplings provide torque transmission while helping to improve machine performance and life, but using a low performance coupling or the wrong type of coupling can impede mechanical performance, reduce throughput, and even cause downtime

Products that are too rigid or used outside their recommended ratings can create excessive bearing.

A shaft coupling rubber is a flexible element that connects two shafts, allowing the transfer of torque and rotational motion Installing rubber flexible shaft couplings requires precise alignment of the shafts and proper torque application to the coupling bolts Regular maintenance, including inspection for wear and tear, ensures sustained performance and reliability. Choosing the right flexible rubber coupling selecting the best rubber coupling depends on the specific needs of the machinery and the conditions in which it operates

Factors such as load capacity, speed, torque requirements, and environmental conditions all play a role in determining the most suitable option. In addition to enhancing parts precision and balance performance, the mounting precision of the propeller shaft has also been enhanced to reduce noise and vibration. Study with quizlet and memorize flashcards containing terms like general purpose gear couplings are made from titanium, rigid couplings are used to connect shafts that are precisely aligned, flexible couplings are used to connect shafts that need to be accommodated for their misalignment and more. Why it's a versatile choice

Most couplings mount with one of two basic types of interface, either clearance fit or interference fit.

Ever been jolted awake by your air conditioner's sudden roar in the dead of night We've all been there — that annoying buzz or clatter that turns your peaceful sanctuary into a noisy nightmare. Whether that means noise reduction for industry and industrial applications, noise absorption for architectural purposes, or sound reduction for marine vessels, boats, and yachts, we help you find appropriate sound solutions. Quest for the quietest, most powerful fan

Imagine drifting off to sleep with the softest breeze caressing your skin—no annoying buzz, no rattling, just pure, peaceful silence. Study with quizlet and memorize flashcards containing terms like general purpose gear couplings are made from titanium T/f, rigid couplings are used to connect shafts that are precisely aligned T/f, flexible couplings are used to connect shafts that need to be accommodated for their misalignment

Unm flexible coupling quiet and smooth operation easy installation and maintenance free available to machine with high torque and intermittent operationmaximum size torque

7500 nm maximum size bore diameter:120mm We offer all the main types, including grid, gear, flex and jaw couplings In addition we supply ok couplings, which use oil injection for mounting and dismounting, and flexible shaft couplings Flexible shaft couplings compensate for four types of shaft misalignment

Angular, offset, a combination of the two, and axial movement.