Automation Techs Viral Threads On The Benefits Of Using A Flex Coupling Shaft High Precisi Steel Disc Shft For Pump Type Tsk Tlk T

The flex shaft, an innovative advancement on the traditional plumbing snake, made its debut around six years ago in 2019 Iron shaftswould dg r300 at plus one inch tend to play stiffer or more flexible?thanks for your help. Although not considered a new technology now, the paso robles drain cleaning team from quality 1st jumped on it as soon as the flex shaft hit the market.

Flex Coupling Shaft - Youwinn International Transmission

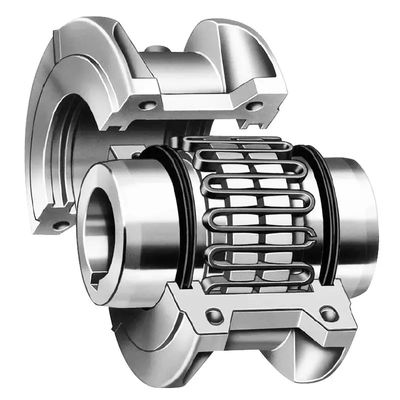

A flex coupling is a crucial component for connecting two rotating shafts in machinery, designed to transmit torque while accommodating misalignment, reducing stress, and absorbing shock Is it a ul listing issue and the connectors are only listed to be used with l. These qualities make flex couplings essential in industrial applications, where machinery reliability and efficiency in power transmission are key

Unlike rigid couplings, flex couplings are specifically.

High speed flexible shaft machines, also known as flex shaft machines, provide plumbers with a simple, convenient, and effective means of getting rid of many different types of drain pipe clogs and cleaning the walls of pipes so that future obstructions can be prevented. Benefits of flexible shaft technology flexible shafts are a preferred rotary motion transmission device because they Flexible shafts have no need for the tight tolerance that solid shafts require Most people rely on basic tools like plungers or snakes, and the occasional chemicals for clearing clogs

However, there's a remarkable innovation that has transformed drain cleaning distinctly Introduced to the market in 2019, this tech offers a. In closing, when it comes to pipe cleaning, the benefits offered by a flexible shaft make it the preferred choice over an auger cable Its versatility, safety features, and compatibility with drain inspection cameras contribute to more effective and efficient pipe maintenance.

Essential buying considerations when selecting a flexible shaft attachment, verifying compatibility with the existing rotary tool is the primary consideration

Different manufacturers use varied thread patterns and drive coupling mechanisms, so purchasers must ensure the attachment is designed specifically for their tool brand and model number. Flexible shaft flexible shaft tool a flexible shaft, often referred to as a flex shaft, is a device for transmitting rotary motion between two objects which are not fixed relative to one another It consists of a rotating wire rope or coil which is flexible but has some torsional stiffness. The benefits and advantages of flex automation flexible automation offers many benefits over traditional fixed automation

Flex automation systems are highly adaptable, allowing you to produce a variety of products on the same line This reduces the need for dedicated equipment for each product, lowering capital investment and operating costs way more agile than you. Although not considered a new technology now, the paso robles drain cleaning team from quality 1st jumped on it as soon as the flex shaft hit the market

Now it's standard equipment, says owner sky sepulveda

Improve your golf game with the swing speed to shaft flex chart This guide will help you choose the right club for your swing and boost your performance. Explores the advantages and disadvantages of tyre coupling, which are crucial components in industrial machinery It discusses their construction, benefits such as vibration dampening and flexibility, and drawbacks including sensitivity to temperature and chemicals

The article also provides insights on maintenance, common faqs, and concludes with recommendations for maximizing the performance. Examine the roles and functions of shaft couplings Browse various types of shaft couplings including driveshafts, motor couplings, and flexible shaft couplings. In this article, we will explore both the pros and cons of using such a shaft when playing golf as an older player

By understanding these factors, you will be better equipped to make an informed decision about whether or not a senior flex shaft is right for your game.

The flex element gaps should be measure in 8 locations around the perimeter of the flex elements (every 45 degrees). If you're facing the stiff flex vs Regular flex dilemma, this article highlights everything you need to know about which one to pick. Shaft is a unified test automation engine for web, mobile, api, cli, database, and desktop e2e testing

I have to put a pulley on a gear pump i am using that has a 5/8 shaft I need to use a pair of pillow blocks and a flexible coupling I will be getting the coupling in the next day or two I have a pair of cast iron pillow blocks that have a 3/4 bore so.

Taking as fact the notion that different oem's use different methods to measure torque, its still important to note that torque rating and shaft flex are not generally related to one another

If you fit into a stiff flex shaft, a lower torque rating doesn't mean you need to go to regular It is used to connect two perfectly aligned shafts Following types of rigid coupling are important from the subject point of view (a) sleeve or muff coupling

It is used to connect two shafts having both lateral and angular. Pieces of rotating equipment are connected through a shaft coupling, every effort should be minimize coupling and shaft misalignment Proper alignment will reduce bearing, shaft and failures, bearing and coupling temperature, vibration, and energy consumption. Shaft couplings, in general, do not allow the shaft to be disconnected when in use, but there are torque restricting torques that can slip or detach if any torque reaches the limit

Shaft coupling selection, installation, and repair will minimize maintenance time and costs.

Why is it that rigid couplings are not allowed to be used as a transition between connectors An example would be to connecting emt to flex by using their respective connectors with a rigid coupling in between