Radial Lip Seal: 2026 Polymer Tech Extends Industrial Pump Lifespan Sealing System Seal With Shaft And Fluid Seal

The graphite ptfe combination offers improved lubricity between the contact of the shaft and sealing lip compared to the old rubber encapsulated, spring loaded lip style oil seals Polymer products should be stored according to described suggestions, helping to maintain the optimum, serviceable properties of the seals through the entire recommended shelf life. Overtime, this extends shaft life and reduces the likelihood of contamination from grooving.

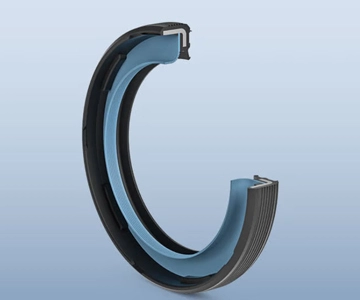

Section of radial lip seal. | Download Scientific Diagram

Our 500 series advanced ptfe rotary lip seal—often referred to as a rotary shaft seal, radial shaft seal, or rotary seal—was developed to significantly improve the performance of elastomeric lip seals with high surface speeds, extreme temperatures, and caustic environments. Useful information and guide on packaging, storage and cleaning of polymer components are provided by industrial standards, such as iso 2230 and din7716 Discover 2026 trends for rotary shaft seals

Extend equipment life and improve performance with novaspect's engineered polymer solutions

Designed for demanding environments, these advanced materials protect pumps, seals, and rotating equipment from wear and corrosion. This may help meet the evolving demands of multiple sectors Here are some recent developments in sealing technology that may create a huge difference in the market Advanced ptfe radial shaft seals

Explore freudenberg sealing technologies' simmerring® radial shaft seals, oil seals, and rotary lip seals for industrial and automotive applications Engineered for durability, low friction, and superior sealing performance. Omniseal ® polymer rotary lip seals were introduced in the early 1970s designed to bridge the gap between conventional elastomer lip seals and mechanical face seals Also known as rotary shaft seals and made with a metal casing, the seal can be manufactured from a variety of advanced materials for sealing elements and control

They perform well in hostile environments with extreme.

Explore skf's radial shaft seals with innovative sealing lip designs for enhanced performance and durability in industrial applications. Whether you're dealing with industrial pumps, automotive engines, or marine equipment, selecting the correct lip seal ensures better performance, reduced maintenance, and longer equipment life. Advancements in mechanical seal technology are transforming pump efficiency and sustainability across industries Explore various industries' wide range of applications and benefits of rotary shaft lip seals

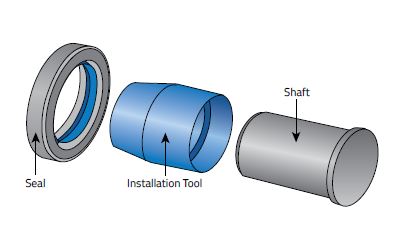

Lip seals are an important part of modern industries, where they help contain lubricants, keep contaminants at bay, and prevent leakage This guide will cover all the essential details about lip seals, from discussing their function to common types and how to install one yourself How does a lip seal function The radial lip seals are widely used in wet environments like ships, water pumps and tidal turbines

The lip seals keep the oil or grease lubricant inside the application and prevents the ingress of water and dirt.

With nmf lip seals, you choose quality, durability and innovative sealing solutions that meet the demands of modern industries. The document is a guide for the selection of radial lip seals It is designed to highlight the elements of a radial lip sealing system and assist in the proper specification of the element parameters. Oil seals, also known as radial oil seals, radial shaft seals or rotary shaft lip seals, are round sealing devices used to seal between two machine parts that rotate relative to each other

They are used to seal lubrication in and/or contamination out, or to separate dissimilar media. Spring energized lip seals require a comparatively high standard of surface quality for the sealing surfaces In general, the better the surface, the better the sealing effect and also the service life of the seal due to less wear. Learn about the importance of lip seal and how they provide reliable sealing solutions for industrial equipment and machinery

About this solution omniseal ® polymer rotary lip seals were introduced in the early 1970s designed to bridge the gap between conventional elastomer lip seals and mechanical face seals

Also known as rotary shaft seals and made with a metal casing, the seal can be manufactured from a variety of advanced materials for sealing elements and control. Find out more about lip seals, how lip seals are designed and manufactured and the difference between radial seals vs rotary seals. The purpose of a lip seal is to create a tight barrier around a rotating or moving shaft, preventing leakage of fluids such as oil, grease, water, or air, and keeping contaminants out of the system Lip seals are essential in pumps, motors, gearboxes, and hvac fans

Rubber lip seal for industry a lip seal is more than just a piece of rubber. Choose our premium radial shaft seals to prevent leaks and block contaminants in automotive, industrial, heavy equipment, agricultural, and marine applications Contact us for custom solutions!