The Mechanical Advantage Strategy Behind The Optimized Motor Keyway Energy Education

The standardized key and keyways are geometrically defined by straight lines and circular arches, which from a point of low stress are not optimal shapes Gib keys, or gib head keys, are tapered and notched machine keys that are used on power transmission keyed shafts to hold pulleys and gears tightly on the shaft. The optimization in the present paper is performed in order to reduce the stress concentration factor.

Mechanical Advantage Explained - Educated Climber.com

Keyed joints are an important part of mechanical power transmission elements shaft and couplings, where it ensures the connection transmits the load, power & rotation without slipping and within the accuracy requirement of the design. Smart innovation, systems and technologies 267vikrant bhateja · jinshan tang · suresh chandra satapathy · peter peer ·. Keys play a fundamental role in ensuring the secure and efficient transmission of power between mechanical components

These small yet critical devices come in a variety of types, each tailored to specific applications and requirements.

At first a design scheme (lay out) is drawn in which the shape of the part being designed and the nature of its connection with other elements are presented in a simplified form while the forces acting on the part are assumed to be either concentrated or distributed in conformity with some simple law; It is always inserted parallel to the axis of the shaft a keyway is a slot or recess (grove) cut out in a shaft and hub of the pulley to accommodate a key. Gain a deeper understanding of the role of keys and keyways in mechanical mechanisms and learn how to optimize their design and implementation. Keyways play a critical role in maintaining the operational efficiency and longevity of rotating machinery

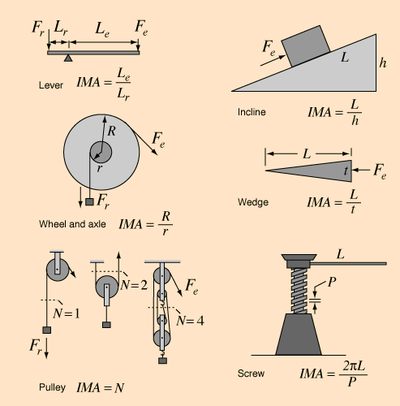

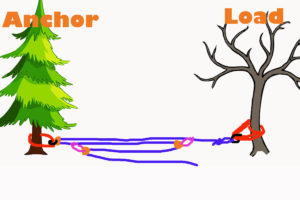

By providing a reliable means to secure components to shafts, they ensure that torque is transmitted smoothly without slippage or loss of energy. One way to keep the motor operating at the maximum power point is to vary the mechanical advantage of the system, defined by the ratio of speed in/speed out, also equivalent to force out/force in When a bicyclist shifts gears to go faster, they change the gear ratio so their legs can keep moving at the same speed but the wheel spins faster. Unlock the benefits of shaft keys with types, materials & applications in our ultimate guide

Perfect for engineers, plants & diy enthusiasts

The keyway and key seat serve a very important role in machine components by allowing a keyed connection between a shaft and a rotating part In the world of mechanical engineering, shaft keyways are essential components for powering your machines But with so many types to choose from, it can be hard to know which one is right for you We've compiled a comprehensive guide breaking down all the major types of shaft keyways and their uses

Find your perfect fit today! A keyway is a slot or groove machined into a component, typically a shaft or hub, to accommodate a key This key serves to transmit torque between the shaft and a connected part, ensuring a secure and efficient mechanical connection. This article offers a guide to keyway milling

Discuss methods for milling keyways and tips for clamping, calibration, and adjustment.

Abstract electric motors are fundamental components in industrial, commercial, and automotive applications, driving a wide range of machinery and transportation systems As global energy demands rise and sustainability becomes a key priority, optimizing electric motor design is crucial for enhancing efficiency, reducing energy consumption, and lowering operational costs There are several types of key shapes A simple mechanical part can reduce manufacturing costs and machine downtime.

In this article we will see the basic difference between slot , holes, groove, and keyways. A key is a machine element which is used to connect a shaft to other machine elements like gears, pullies, couplings, sprockets or flywheels. Order feather keys for precision mechanical components today request a quote for shaft keys in the size and material you need, or contact us to discuss modified or custom feather key options. The concept of mechanical advantage is a cornerstone in the field of mechanics, offering insights into how simple machines can be employed to optimize work

By understanding the principles of mechanical advantage, one can grasp how force and distance interact to make tasks easier, more efficient, or possible when they would otherwise be impractical

This article delves into the fundamentals of.