Pressure Data: Why Compression Fitting Dimensions Are Crucial For Labs Pp Manufacturer & Supplier Tomeex

The correct dimensions for compression fittings are crucial for ensuring system integrity, safety, and optimal performance Learn more about the differences between the most commonly used pressure fitting/adapter standards in fluid systems. In combination with a high pressure tubing material like steel, large compression fittings can often be used at pressures in excess of 10,000 psig

Crucial Standard Dimensions & Details Including a Magnificent

How much pressure can a compression fitting handle Learn about their uses, benefits, and how to choose the right fittings. Material, size, industry standards, and the crucial role of installation quality.

Most laboratory fitting systems work through external compression onto the tubing's outer wall, accomplished by the ferrule's tapered nose

Ferrules come in many shapes and sizes. Gas fittings on gcs are compression fittings, and most labs plumb their lab gases using compression fittings as well Compression fittings consist of a compression nut or screw, a ferrule, and a fitting body Metric and imperial fittings compression fittings are supplied in either metric or imperial tube sizes

It is very important that types are not mixed or used on the incorrect tubing. In this guide, we'll explore the fundamentals, installation process, and key considerations for using compression fittings effectively. The compression fitting is designed to swage onto the tube with the first application This is why it is so important to know what the compression fitting is and how it works

The compression fitting is four independent parts as shown above

The first time the nut is tightened onto the fitting body, the back and front ferrules are pushed into the tube For a range of sizes of compression. The benefits of compression tube fittings leak resistance One of the key advantages of compression tube fittings is their excellent leak resistance

This reliability is crucial in industries where safety and efficiency are paramount Compression nut features strong buttress threads engineered for easier tightening during installation These fittings consist of a few key components including a compression. When selecting a compression fitting for a specific application, it is crucial to consider the working pressure of the system and ensure that the chosen fitting can handle the intended pressure without compromising safety and performance.

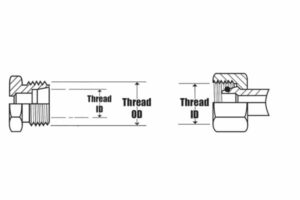

It is important to understand the difference between 'nominal' dimensions and 'outside diameter (od)' dimensions

Nominal is the term used to describe most pipe and fitting measurements in the plumbin Explore the essential types, applications, and benefits of tube fittings for industrial and sanitary systems Learn how choosing the right tube fitting supports efficiency and safety. Why is it important to select the right size compression fitting

Since compression fittings have the ability to withstand high pressure and extreme temperatures, ensuring that you select the right size compression fitting is critical for a safe, tight, and secure fit. Air compressor fittings play a crucial role in the functionality of your air compressor system They come in different types and sizes, allowing you to customize your setup based on your specific needs Proper fittings help maintain optimal pressure and prevent air leaks, enhancing performance and efficiency.

Compression fittings are mechanical connectors used to join pipes or tubes in fluid or gas systems, eliminating the need for welding, soldering, or adhesives.

Compression fittings come in many shapes and sizes, as well as elbows, t's, tubing union configurations and more ression fitting body The functioning principle of each component also remains more or less the same between designs Tubing is inserted into the end of the fitting, and the nut/screw is tightened, forcing the ferrule(s) The line contact barb is the preferred design

On the line contact barb fitting, the edge of the barb makes a line contact, as opposed to a surface contact, with the tubing wall In addition, the tubing makes a surface contact with the fitting shank When the fitting is properly designed, the tubing expands over the line contact barb and then contracts back onto. Low and medium pressure tubing connection work where excessive vibration or tube movement is not involved

Long nut recommended for additional vibration resistance.

Pipe fittings are an important part of the pipeline system, so how are the sizes of pipe fittings determined Of course, there are different production standards. Discover everything you need to know about metric compression fittings in our guide