Why The Future Of Automation Depends On Industrial Parts And Electric Motors Trends What Will Change In

The future of industrial automation starts with smarter electric motors that think, adapt, and connect Companies that specialized in electric motor manufacturing adapted various motor technologies, such as synchronous and asynchronous motors, to better suit the needs of specific industries. Smart motors integrated with iot and ai will drive the next wave of industrial innovation

Industrial automation trends. What will change in industrial automation

We're shifting from traditional machines to intelligent systems. Learn how materials impact efficiency, performance, and lifespan! Industrial automation has emerged as a cornerstone of modern manufacturing, logistics and utilities

At the heart of this revolution lies control systems—sophisticated frameworks comprising sensors, actuators, controllers and communication interfaces

Our analysis of the 8 key industrial automation trends highlights the critical interplay between technological advancement and workforce development for manufacturers and producers seeking to achieve business success and gain a competitive edge. In today's rapidly advancing industrial landscape, automation is becoming the backbone of modern production systems Industrial motors play a pivotal role in this transformation, providing the energy and precision needed to drive automated systems These motors are the silent workhorses in factories, warehouses, and manufacturing plants, fueling everything from robotic arms to conveyor belts.

Learn about the importance of industrial automation in modern manufacturing, and some of the key technologies and trends that support it. Industrial process automation is changing manufacturing by using technology to reduce the need for human involvement From robots assembling products to smart systems managing inventory, factories are being transformed This article will explore the successful elements behind industrial automation.

In 2000, global production of electric motors reached 200 million units

This period marked the early stages of increased industrial automation and the adoption of electric motors in various sectors The rise in production was fueled by the need for more reliable and efficient power sources in manufacturing and other industrial applications. Advancements in air and electric motor technologies are revolutionizing industrial automation Get a closer look at how industrial automation, ai, and robotics are shaping the future of manufacturing

Learn how automation is enhancing factory performance and driving smarter processes through 2025 and beyond. Electric motors are at the center of a silent revolution—one driving sustainable progress across evs, aerospace, industrial robotics, and smart manufacturing With motors consuming 46% of global electricity, the smallest gain in efficiency can create transformative impact. The rise in production was fueled by the need for more reliable and efficient power sources in manufacturing and other industrial applications

By 2010, production had surged to 350 million units.

Learn about electric motors, their types, uses, and how they work Explore ac, dc, ecm, gear motors, and more. Conclusion electric motors are a fundamental pillar in the electrical business, driving technological progress, energy efficiency, and sustainability across various industries From industrial applications to consumer electronics, electric motors power the future of technology and innovation.

Here at industrial parts we believe that electric motors make the world go 'round We also understand that in an urgent or breakdown situation time is a precious commodity in getting your manufacturing processes back up and running normally. Large industrial electric motors are used in almost every major aspect of life Learn more about what these motors are, and how they work.

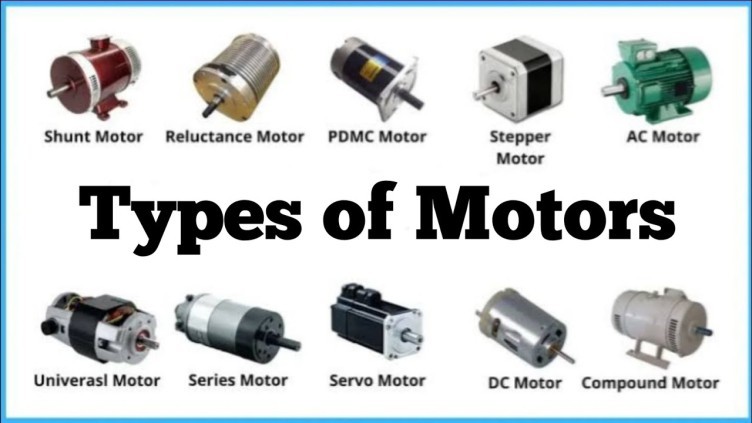

Understanding the different types of electric motors is critical for selecting the right one based on speed, torque, power supply, and control requirements

This guide explains the major types of motors— ac motors, dc motors, stepper motors, servo motors, and linear motors —and their common applications in detail. With the advent of sustainable mobility and the increasing use of electric vehicles, electric motors are gaining even more importance The design drivers of modern electric motors for evs are primarily focused on energy efficiency and reducing power losses. Where automation meets precision your trusted industrial automation parts distributor an semiconductor web resource as a premier industrial parts supplier owned and operated by asap semiconductor, we serve as your sourcing solution for industrial automation parts, industrial fasteners, electronics, and much more.

Learn about the different types of motors and what to consider when choosing the right one for your automation needs. The types of electric motors convert electrical energy into mechanical energy, optimizing efficiency in sectors such as automation and transportation. Contact us, industrial parts and electric motors inc in memphis tn, power for production, after hours help available after 4:30pm Industrial automation is a trend that has radically transformed manufacturing and production around the world

At the heart of this revolution are electric motors, essential devices that drive machinery and processes in a variety of industries

In this article, we will explore the importance of electric motors in industrial automation and how they are contributing to increased efficiency and. The conversion of electromagnetic energy into the work performed by the industrial electric motors It produces a linear or rotational force Discover the structure of electric motors, from stators and rotors to windings and bearings