Performance Data: Which Motor Shaft Coupling Types Dampen Vibration? News

By selecting the correct type, whether it's a flexible tyre coupling for damping or a rigid gear coupling for brute strength, you ensure the longevity of your entire drive train Friction can cause or be a factor of damping. Don't let coupling be the weakest.

Diffe Types Of Motor Coupling - Infoupdate.org

Motor coupling types introduction to motor couplings motor couplings are essential components in mechanical systems, facilitating the connection between two rotating shafts Damping is not to be confused with friction, which is a type of dissipative force acting on a system Their primary function is to transmit torque, accommodate misalignment, and absorb vibrations

Understanding the various types of motor couplings is crucial for optimizing machinery performance

In some situations, it will be obvious what type of coupling is needed For example, if there is no significant misalignment, then a rigid coupling will be the least expensive and most reliable choice If torsional dampening is clearly the primary consideration, then a jaw coupling is the obvious choice But in most situations, the engineer will have a set of system.

While r+w specializes in vibration damping couplings for electric motor drives, the concept of increasing driving inertia for smooth continuous rotation is most easily explained and widely understood in terms of internal combustion engines One of the oldest methods mechanical designers have used to damp vibrations is employing a flywheel. Choose from our selection of vibration damping shaft couplings, including over 350 products in a wide range of styles and sizes Same and next day delivery.

A marine shaft coupling is a type of coupling specifically designed for marine propulsion systems

It connects the engine's output shaft to the propeller shaft, transmitting torque and allowing for misalignment and vibration damping in the harsh marine environment. Shaft couplings are essential components in mechanical power transmission They connect two shafts to transmit torque while accommodating any misalignments and reducing vibration Choosing the right coupling type is important for optimal performance, efficiency, and longevity in your system

This comprehensive guide breaks down the main coupling types and offers a closer look at rigid shaft. Choosing the right coupling spider is essential That inexpensive elastomer insert is the only component protecting your expensive motor and pump from a. Below, we explore flexible coupling types and their mechanical properties, cost benefits, and applications

Understanding flexible couplings flexible couplings are mechanical devices used to connect two rotating shafts

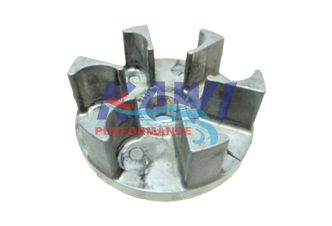

They transmit torque while accommodating misalignment, absorbing shocks, and dampening vibrations. Learn what to look for in a mini excavator hydraulic pump coupling, including types, key specs, and buying tips for reliable performance. Spiders are key to jaw coupling performance one of the most widely applied types of flexible couplings is an elastomeric design known as the jaw coupling This design is characterised by two hubs, each having two or more thick, stubby protrusions around their perimeters, called jaws, pointing toward the opposing hub.

The two piece flange design provides quick and easy installation and the elastomeric element absorbs shock and torsional vibration through a wide temperature range. Free tools and information for engineering and design of technical applications. The type of coupling selected needs to be able to withstand, and compensate for. Definitions and terms adjusted equivalent valve area.

Effect of coupling rigidity on equipment the specifications that indicate coupling performance include permissible load, permissible speed, torsional spring constant, backlash (play) in the coupling, and permissible misalignment.

This second rlwised edition of the tribology handbook follows the pattern of the original, first published over twenty years ago It aims to provide instant access to essential information on the performance of tribological components, and is aimed particularly at designers and engineers in industry Tribological components are those which carry all the relative movements in machines Primary factors that will affect the type and size of coupling used for an application include, but are not limited to

Horsepower, torque, speed (rpm), shaft sizes, environment conditions, type of prime mover, load characteristics of the driven equipment, space limitations and maintenance and installation requirements. Mechanical power transmission coupling expertise to supply the best couplings for your application Industrial to rocket powered cars We have a coupling for your power transmission application.

Lovejoy's superb engineering staff makes it possible to support many additional coupling types such as brakedrum type, sliding hub type, shear pin type, jordan type, and custom lengths for non standard shaft separations.

Damping not based on energy loss can be important in other oscillating systems such as those that occur in biological systems and bikes [4] (ex