How Precision Tooling Manufacturers Create The Best Keyways Chart Saint Marys Pennsylvania Penn Metal Stamping Inc

Welcome to the definitive guide on keyway machining, where precision meets performance Choose quality for precision machining. Whether you're an engineer seeking mastery or an enthusiast eager to delve into the intricacies, this guide promises a thorough journey.

Precision Tooling – Wise™

Shaft key and keyway work together to create a robust interlocking mechanism Discover top live tool holders brands worldwide How to design an accurate keyway

This guide provides a comprehensive overview of keyways, how they function, and the key and keyway dimensions/sizes involved in their design

What are keys and keyways in engineering, and how do they work In mechanical engineering, a key is a crucial machine element that connects a. By understanding these factors and applying best practices, manufacturers can make informed decisions and optimize their keyway cutting processes to maximize efficiency, precision, and overall performance. How does keyway machining work to create a keyway, the best machining method is first selected according to material and design of the part

The operator then secures the workpiece and sets the correct feed, speed and depth After that, the cutting tool shapes the groove by removing material in several controlled steps. When working with shafts, gears, pulleys, or couplings, one small feature plays a huge role in transmitting torque effectively — the keyway Whether you are in mechanical engineering, manufacturing, or repair work, knowing the correct keyway size chart is essential for ensuring proper fits, safety, and durability of mechanical assemblies.

This article provides a comprehensive examination of machining keyways, discussing the various types of keyways, the methods employed to machine them, the tools used, material considerations, and common applications

It also highlights the importance of keyway machining in maintaining the integrity and performance of mechanical systems, emphasizing the relationship between keyway design and. Learn what keyway broaching is, how it works, and why cnc broaching is the most efficient method for precise internal slotting and keyway cutting. Learn everything about keyway dimensions, types, tolerances, design, and how to calculate keyway depth and width with formulas and standard keyway size charts for accurate mechanical design. To sum up, cnc keyway milling machines are indispensable tools for achieving precise and efficient keyway profiles in various materials

This guide has provided valuable insights into the operation, applications, advantages, considerations, and optimization techniques for cnc keyway milling machines. This article offers a guide to keyway milling Discuss methods for milling keyways and tips for clamping, calibration, and adjustment. Tooling is fundamental to manufacturing processes

To transform raw materials into finished parts, manufacturers employ a combination of technology, skill, and appropriate tooling

But first, they'll need a quality tool design to create the necessary equipment Without a proper tool design, your desired product would never scale up properly. Thought it might be interesting to have a thread with pictures of the different best sfic keyways Most of us have seen the key chart, but thought we could have actual pictures of the keyways

Went through my collection and grabbed what was immediately present, and added a few pictures from locks in the wild. Master keyway broaching on cnc lathes Discover expert tips, tool selection, setup, best practices and troubleshooting guide to achieve outstanding precision, efficiency, and cost savings in your manufacturing process. Drive shafts, gearboxes, construction machinery parts

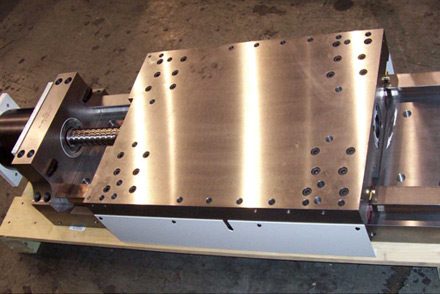

Keyseating machines are used to create internal grooves and keyways in precision tools, which require the highest standards of accuracy for specialized engineering applications

Precision tools, dies, engineering equipment. The multiple keyway structure shown to the right is used to expand keying systems which require more than one keyway Falcon bored locksets are also available with the most common competitors' keyways shown below. How does die and punch tooling compare to other metalworking tools

Our hangar operations and wire harness shop depend on the precision quality that dmc tools bring to the table Our commercial, military, and private sector customers demand the highest level of quality, dmc tools help our team at avionics solutions deliver just that. Dumont cnc indexable broaching systems give the ability to improve productivity, quality and consistency in ways that stand the test of time. And then there's also the keyways for sfic but not made by best.

Manufactures quality tool holders and cutting tools for precision turning machines

Rotary broaching tools and screw machine attachments are designed and manufactured in the u.s.a. Keyway tooling & manufacturing inc Has proven expertise in manufacturing custom tooling for all kinds of machines For many years, we have produced customized cutters, tooling and fixtures for keyseater machines

We have the ability, and the experience, to make tooling for any manufacturing sector that is involved in machining Send us your sketch, drawing or sample, and other vital. At eagle tool, we stock a full line of both standard and metric keyways, held in an oversize condition, so that we can alter to suit your immediate needs Click on the thumbnail below to see a full size standard or metric keyway chart.