Synchronous Drive Gearbelt Pulleys: 2026 Precision In Motion Control New Solutions For Optics And Photonics

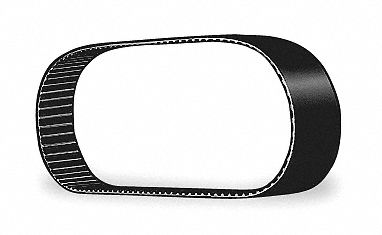

Precision timing belts, pulleys, sprockets, and chains for synchronous drive systems why choose synchronous drives Choose from trusted brands, filtered by belt type and size specifications. Same and next day delivery.

Precision Motion Control and Its Applications | PPT

Synchronous drive gearbelt pulleys are essential components of machinery used in various industries In order to ensure smooth operation […] These pulleys are designed to transmit power from one shaft to another while maintaining constant speed and torque, ensuring optimal performance of your machinery.

Timing belts and pulleys allow adjustment of speed and torque while connecting mechanically rotating components

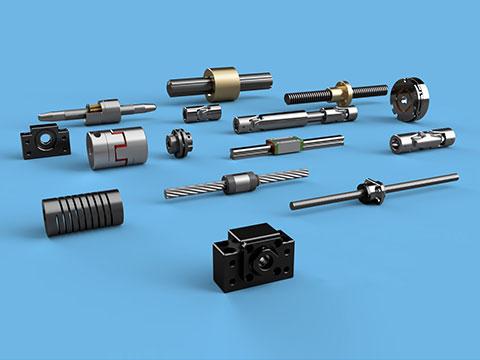

Components are available in a range of pitches and number of teeth for power transmission applications Toronto gear works manufactures custom and standard synchronous drive products that include timing belt pulleys, roller chain sprockets, and more York industries is an expert in small synchronous drives, with over 80 years of success in manufacturing custom and standard timing pulleys, gears, gear racks, and custom assemblies, and as a supplier of timing belts. These kits typically include precisely matched timing pulleys and belts, designed to eliminate slip and maintain perfect synchronization between shafts

Manufactured to exacting tolerances from materials such as aluminum, steel, or plastics, our pulley. Overview of synchronous belt and pulley components synchronous belt a synchronous belt, commonly known as a timing belt, is essential in power transmission systems The teeth on the inner surface of the synchronous belt engage precisely with the grooves of a pulley, ensuring no slippage and highly accurate motion transfer between shafts Timing belt pulleys or synchronising pulleys are used with drive solutions with timing belts

Transmission accuracy, service life and also smooth and quiet running are crucially influenced by the precision of the interaction between the timing belt and the pulley

Synchronous pulleys are classified according to the defined standards of the timing belts, number of teeth, pitch, pulley width and. Designatronics offers a wide variety of drive belts, pulleys, and cables for use in all different applications Contact a sales rep now to learn how we can solve your motion needs! Split taper & qd bushing styles, as well as, finished and minimum plain bore.

A synchronous drive gearbelt pulley ensures precise motion transfer in mini lathes by using a toothed belt to eliminate slippage, providing consistent speed control and enhancing machining accuracy. Types of pulleys include synchronous drive gearbelt pulleys, precision motion control pulleys & many more Sprockets and idlers pair with synchronous drive belts to efficiently synchronize mechanical power systems and transfer motion Select based on product type, number of teeth, pitch, series, and more.

Choose from our selection of gearbelt pulleys, including over 950 products in a wide range of styles and sizes

Precision motion & automation predictive maintenance switchgear, transfer switches & controls all ac/dc drives & controls ac drives dc drives kits all bearings mounted bearings unmounted bearings specialty & plain bearings bearing parts & kits all conveyor technologies plastic modular chain & belt tabletop chains conveyor sprockets & wheels. Calculation for sizing synchronous belts and pulleys when it comes to optimizing the performance of mechanical systems, the proper sizing of synchronous belts and pulleys is of utmost importance Synchronous belts, also known as timing belts, are used to transmit power and motion between two or more rotating shafts