Forum Debate: Can You Trust A Digital Pipe Tap And Drill Chart For Cnc? Metric Stndrd Helicoil Tp Chrt Infoupdte Org

Standard for tapered threads used on threaded pipes and. Find the latest downloadable pdf charts and guides, including a&m industrial's free tap & drill chart, decimal equivalent chart & more. Basic tap size charts for strong holes and threads

Metric Standard Helicoil Tap Drill Chart - Infoupdate.org

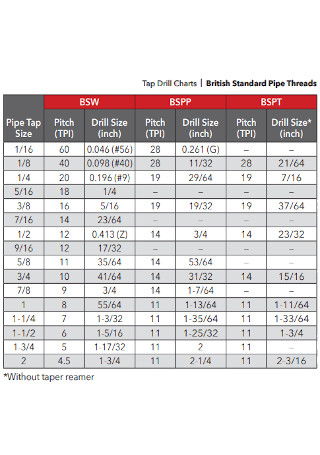

Learn about metric, unc/unf, and pipe thread standards, as well as tips for accurate drilling and tapping. I keep 8.5by11 print out by each machine of course check each and every line for mistakes and do not use it if you are going to have problems. A tap drill chart is a table that tells you which drill bit to use before tapping threads

Drill the hole too large and the threads will be shallow and prone to leakage

Drill too small and the tap may bind or even break when cutting overly deep threads. But to a newcomer, they might not appear to make a whole lot of sense Add in some potentially complicated sizing systems, and even a simple tap drill chart might require some explanation. Cnc taps are tools designed to create accurate holes in various materials, from metals and plastics to composites

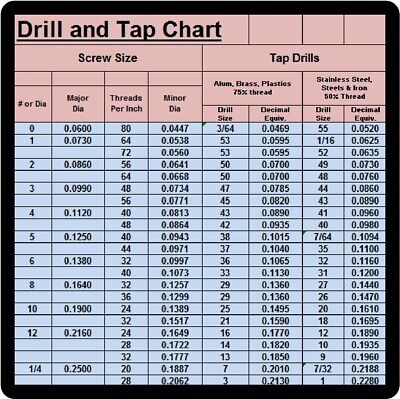

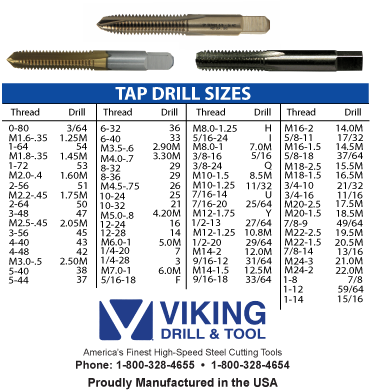

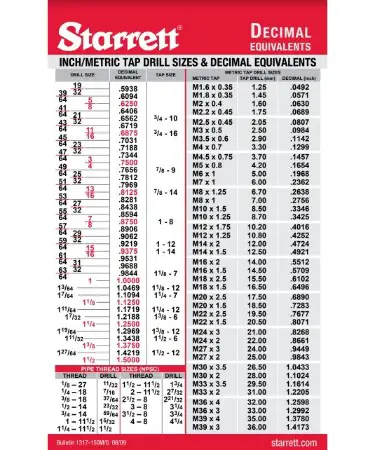

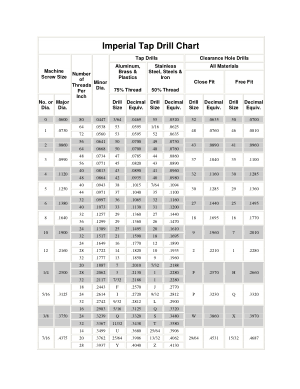

Chart for determine what size drills to use for tapping Metric, inch, pipe, in coarse and fine thread. Download and print the industry's most comprehensive tap and drill chart, complete with standard, metric & plug tap and drill sizes, and more. In cnc machining, one of the most important tasks is creating threaded holes that fit perfectly with bolts, screws, or other components

To achieve this, machinists must first drill a hole with the correct size drill bit and then cut threads using the right tap

Using the wrong size can result in stripped threads, poor fit, or part failure Understanding the relationship between drill bit size. Comprehensive tap size chart for manufacturing and machining Includes fractional, metric, and numbered screw sizes, decimal equivalents, pitch, and recommended tap drill sizes for threading operations.

The taper rate for all npt threads is 1⁄16 (3⁄4 inch per foot) measured by the change of diameter (of the pipe thread) over distance The angle between the taper and the center axis of the pipe is 1° 47'′ 24″ (1.7899°). Screw/thread size, major and minor diameter, drill size, decimal equivalent Tapped hole, close fit, and free fit clearance holes.

Choose from our selection of reference charts, tap and drill reference rulers, drill bit size identifiers, and more

Same and next day delivery. Comprehensive drill size chart for manufacturing and fabrication Includes fractional, metric, wire gauge, and letter drill bit sizes with decimal equivalents for quick reference. Discover the updated tap drill size chart with metric and imperial sizes

Download the free printable pdf and master accurate hole sizing. This drill tap chart provides the information you need to properly drill and tap holes This chart includes values for screw sizes and the proper size drill bit to use to make the hole for the tap. The threading process as you would expect, taps come in all forms and sizes in order to accommodate standardised screw threads

Therefore the tap drill chart is extremely important

To create a thread properly, one would need a set of three taps that correspond to the same bit size Namely the bottoming, the intermediate, and the taper tap. Excel tap drill chart for inch and metric chart is in excel file format which the free openoffice will open By having chart in excel format you can check for mistakes and or edit it as you want