The Information Gain Behind High-torque Control Found In Any Bodine Motor Troduction To Constants For Fractional Horsepower Gears

With modern electronic control systems, the torque control is fast Learn about the different components and connections involved in the wiring process and ensure a safe and efficient electrical setup for your bodine gear motor. The drive system can have a very high dynamic speed response

Gearmotors - AC & DC Electric Gear Motors - Bodine Electric Company

Torque can be changed instantaneously if the motor is fed from an ideal current source Find out how to wire a bodine electric gear motor using a detailed wiring diagram To address these challenges and enhance overall motor control, this article introduces a new approach based on neural networks

Direct torque control method is specifically designed for doubly fed induction motors and utilizes an artificial neural network.

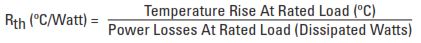

Accurate motor torque control relies on feedback loops and sensors that work together to provide essential information for effective torque management These components monitor the motor's performance and make adjustments to ensure smooth and efficient operation, enhancing the system's responsiveness and reliability. This involves calculating an estimate of the motor's magnetic flux and torque based on the measured voltage and current of the motor. It has benefits such as reduced torque and flux ripples, fast dynamic

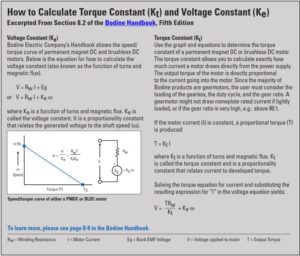

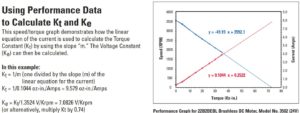

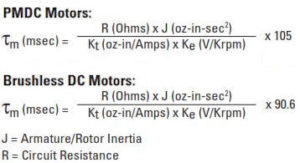

Motor torque will not depend on load Tm = km i advantage of linearity Ideally, the output signal is a constant gain times the input signal, with no distortion This section of the bodine handbook refers to permanent magnet dc (pmdc) gearmotors and motors

We review their main features and benefits such as

This type of control enables precise control over the motor's speed, position, and torque In the classical dtc induction motor drive a voltage vector is applied for the entire period, and this causes the stator current and electromagnetic torque exceeds its reference value early during the cycle, causing a high torque ripple. Bodine electric company is a leading manufacturer of fractional horsepower gearmotors, motors, parallel shaft gearmotors, and motor speed controls Bodine electric offers over 1,300 standard products and thousands of custom designed gearmotors, motors, and speed controls.

Gearmotors function as torque multipliers and speed reducers, requiring less motor power to drive a given load The gear housing design, the gearing type, gear lubrication, and the. Of torque, which is nearly twice the torque of any previous bodine product. Browse high torque gearmotor solutions from bodine electric company

We offer parallel shaft gearmotors, accessories and more.

Modern vfds can now perform torque control for winding/unwinding and other applications, expanding options for equipment designers Variable frequency drives (vfds) are commonly used by automation systems to vary the speed of an ac electric motor, but there is another class of applications where torque control, regardless of speed, is the primary goal Kevin kakascik at automationdirect wrote. They are ideal for mobile, battery powered, and solar powered applications

These new gearmotors are o¦ ered with 12 gear ratios (5:1 to 240:1), and expand the bodine pmdc gearmotor torque. I picked up a bodine electric dc motor speed controller with torque control ($10 at garage sale) I was hoping to use it either on my milling machine. Quick reference this manual contains the basic information needed to install and operate bodine dc motor speed control model 1865

This manual does not profess to cover all details or variations in equipment, nor to provide for every possible contingency associated with installation, operation, or maintenance

No warranty of fitness for purpose is expressed or implied Learn about motor control basics & drive operating modes Covering ac & dc motor torque control, motor velocity control & more Bodine offers four ac torque motor frame sizes

30r, 42r and 48r and k2 Bodine motors with 130vdc windings are used in conveyors, turntables, and other applications where adjustable speed and constant torque are required Browse and download the latest bodine electric company catalog Our standard product guide can help you find the gearmotor for your application.

.png)