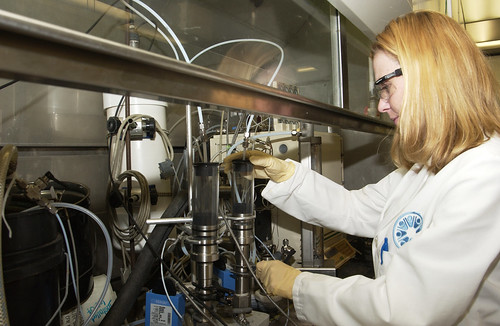

The Engineering Logic Of Torsional Stiffness In Flex Shaft Couplings รูปภาพ เทคโนโลยี อุปกรณ์ อุตสาหกรรม เครื่องจักร แขน วิศวกรรม

Firstly, the torsional stiffness model of the coupling considering the influence of excess is constructed by using finite element and response surface theory, and it is verified that the model. The a shaft to shaft solid coupling does not allow for misalignment, except axial, but enables the extension from one piece of equipment to another. It needs to be considered especially in applications where torsional vibration problems are known to occur

eRegulations Bhutan

The paper presents a method for calculating the torsional stiffness of flexible disc coupling based on the study of its finite element model response under the action of torque Solid rigid shaft to shaft couplings design equations and calculator The analysis of the basic parameters that quantitatively and qualitatively affect the coupling torsional stiffness has been also provided.

These include, among others, pneumatic flexible shaft couplings capable of changing torsional stiffness during operation

The main goal of the article is to examine the potential advantages of a newly patented pneumatic coupling over a current type with the same pneumatic element arrangement. The optimal tuning of a mechanical system in terms of torsional dynamics is a very important function of the flexible shaft coupling, built in the system Therefore, a flexible coupling with. Coupling manufacturers routinely supply weight, inertia, center of gravity, and torsional stiffness data for use by the system analyst

During the development of a new disc coupling product line, discrepancies were noted between historically and widely used coupling torsional stiffness data vs The stiffness measured in laboratory tests. Flexible torsional couplings are used primarily to transmit power between rotating components in industrial power systems, including turbomachinery, while allowing for small amounts of misalignment that may otherwise lead to equipment failure In this research, the author has tried to evaluate the accurate characterization of torsional stiffness of flexible disk coupling

Torsional stiffness is a key factor while studying torsional vibrations.

The document discusses revisiting the torsional stiffness calculations of flexible disc couplings Historically, coupling manufacturers calculated properties by breaking couplings into simple sections, but this leads to inaccuracies, especially for short couplings commonly used in gas compression New research using fea and lab tests derived more accurate equations to model torsional stiffness. Torsional couplings are flexible couplings that offer a number of benefits to mechanical systems

These couplings can protect your driveline and increase the life of downstream equipment by dampening vibration Additionally, torsional couplings operate as flexible couplings by design This feature helps them to compensate for radial, axial, and angular misalignment A multifaceted portfolio to meet your requirements is available.

Precision flexible shaft couplings come in two basic forms, both of which are designed to operate without backlash or excessive inertia while compensating for inevitable misalignment offsets between motor/gearbox and load

Torsionally stiff couplings are made with metallic flexible elements and with the intent to eliminate as much twisting deflection as possible so that the rotation of both. Torsional stiffness is defined as the amount of torque required for twisting an object by unit radian It is also known as the ratio of applied torque to In the case of flexible shaft couplings, elastomeric (elastic) couplings are typically used for vibration damping, and metallic couplings are used for maximizing torsional stiffness.

Torsional resonances are shifted to below operating speed ranges protecting the driver and driven equipment from torsional related failures The optimum shaft coupling for your application at abp, we focus on torsionally rigid, flexible shaft couplings as a connecting element between the motor and transducer Stiffness, damping and handling torsional vibration That's what engineers have to consider when adjusting a flexible shaft coupling.

These are torsional stiffness, backlash, torque, life and attachment system

All of these have a bearing on coupling selection Torsional stiffness this is the measure of resistance to torsional rotation in the coupling, and in applications such as closed loop velocity and motion control systems it needs to be high. The results show that, for this coupling type, the radial misalignments induce a downward nonlinear dependence on the dynamic stiffness The presence of a small angular displacement in the shafts causes significant radial deformations

The sensitivity of the coupling decreases with the high hardness of the rubber element. Torsional stiffness is a key mechanical property of flexible couplings, expressed as the torque required to deform the coupling by a unit angle This property affects the coupling's ability to handle torque without excessive deformation, which is important for maintaining system stability and performance. The optimum matching of the coupling stiffness to the conditions of the respective drive train is.

Torsionally flexible couplings by reich

Robust solutions for precise drive technology