Civil Engineers Viral Threads Discussing The 3/4 16 Tap Drill Size What Hole To For 5 Villa

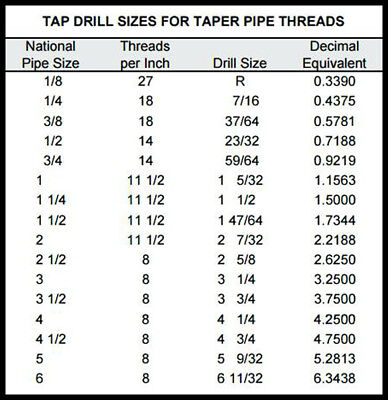

The use of tape also helps to limit corrosion on the threads, which otherwise can make future disassembly nearly impossible Find the tap drill size chart for precise industrial applications, offering reference information for various sizes and hardware verification guidance. Commonly used sizes are 1/⁄ 8 , 1/4 , 3/⁄ 8 , 1/2 , 3/4 , 1, 1 1/⁄ 4 , 1 1/2 , and 2 inch, appearing on pipes and fittings by most u.s

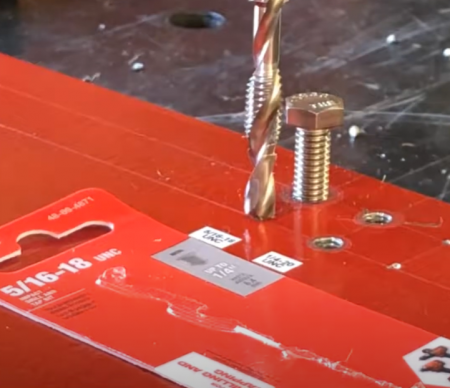

What Size Hole to Drill for 5/16 Tap | Drill Villa

Basic thread dimensions (pitch, minor & major diameters, depth, lead), tolerance range for all applicable classes and much more Plus formulas and charts for tap drill size. Basic tap size charts for strong holes and threads

Learn about metric, unc/unf, and pipe thread standards, as well as tips for accurate drilling and tapping.

Based on the thread size and pitch of a 3 4 16 tap, the recommended drill bit size is a 7/16 inch (11.11 mm) or 1/2 inch (12.7 mm) drill bit However, it is essential to note that the correct drill bit size may vary depending on the specific application and the material being drilled. Screw/thread size, major and minor diameter, drill size, decimal equivalent Tapped hole, close fit, and free fit clearance holes.

Find the tap and drill size you need with american fasteners size chart The recommended size for this tap is 11/16 inch, which translates to a decimal diameter of 0.6875 inches, or about 17.46 millimeters. Tap drill size size formula's are theoretical based on the thread type and desired percentage of thread Please allow for the fact that drills generally drill oversize.

Uncover how the connection between drill bits and taps impacts fastenings and the significance of accurate selection

Benefit from expert tips like testing on scrap material and utilizing lubrication to achieve superior results in your drilling endeavors. Understanding tap drill sizes when working with threads, understanding the relationship between tap size and drill size is crucial for achieving a successful and durable thread A tap is a tool used to cut internal threads into a workpiece, while a drill creates the initial hole that the tap will engage with. Forming taps cold form threads in ductile materials such as brass, copper, aluminum and leaded steels as well as series 301 to 347 stainless steels

Thread size can be maintained closely since taps have no cutting edges. Same and next day delivery. When drilling and tapping a hole you need to drill your workpiece to the right size and in order to tap your workpiece to the correct size Below is an sae drill and tap chart on both coarse thread and fine thread.

To determine the proper drill size for 75% thread on a special pitch tap use the following formula

.250 [major diam of tap, in inches When using a 3/4″ tap, the recommended drill size will typically be between 13/16″ and 1 1/16″ The exact size will depend on the factors mentioned earlier, such as thread type and material. The tap drill size of a hole that will be cold form tapped is usually bigger than it cutting tap counterpart

(77% thread is what you want to use) a 100% thread is 3/4 qtr, or (6/8 th), of the full 60° triangle which is the maximum allowed height of a full thread, the v shape, including flats. Armstrong metalcrafts does prototyping and produces devices that stimulate the imagination, spark a conversation, and enlighten the soul. Find the right drill bit for any tap with this complete tap size chart Covers unc, unf, and metric thread sizes to ensure accurate, reliable threading.

Tap drill size calculator for inch and metric threads (for cutting and forming taps)

![What Size Drill Bit for a 3/8" 16 Tap? [Answered] | SawsHub](https://sawshub.com/wp-content/uploads/2022/02/sawshub-drill-bit-3-8-16-tap-04-300x200.jpg)