Machinists Viral Ranking Of The Most Durable Types Of Shaft Keyways In 2026 Studio Tier List Maker Tierlists Com

Shaft keys come in a wide variety of types and shapes and can be divided into four categories and subcategories Read through the rest of this article to learn more about the types of shaft keys, how they work, the most popular materials used, and the various advantages and disadvantages of shaft keys. Of the above types of keys, the parallel square key and woodruff key are probably used more widely than others due to ease of use and cost.

Shaft key & keyway | Key types | Keyed Joint application & benefits

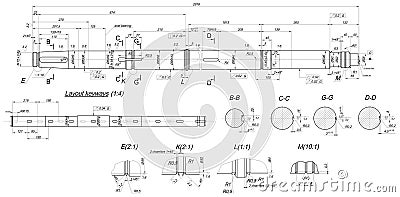

In this blogpost we will cover what keyway machining is and its main methods The best types of wood for furniture depend on what aesthetic you look for, your budget, and the amount of wear & tear you expect to endure. We will also see step by step procedures, common issues and important uses for producing high precision shafts

Basically, a keyway is a slot or groove that is cut into a hub or a shaft with high precision.

This article provides a comprehensive examination of machining keyways, discussing the various types of keyways, the methods employed to machine them, the tools used, material considerations, and common applications. Whether you are involved in automotive applications, machinery building, or robotics, understanding the various types of keyed shafts and their specific uses is crucial. Understanding the various types of keyways—standard, metric, woodruff, splines, and custom solutions—is essential for engineers and designers who aim to enhance the reliability and efficiency of their machinery. Keyways secure gears onto shafts, ensuring synchronized rotation and torque transfer

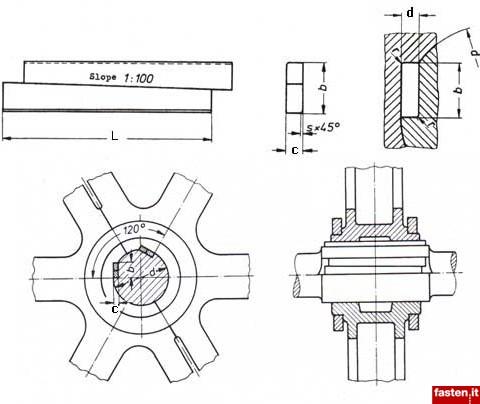

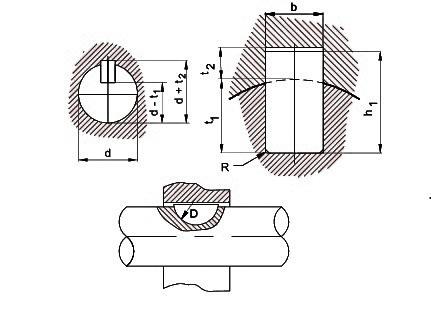

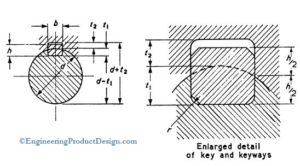

In belt and chain drive systems, keyways prevent slippage between the pulley or sprocket and the shaft. Complete guide to shaft keys covering the motor key types, dimension formulas, strength calculations, material selection, and practical case studies for reliable torque transmission. Proper design and machining of keyways is crucial to ensure a secure and reliable connection between the parts, minimising the risk of failure or slippage Keyways and keys come in various types, including square keys, rectangular keys, woodruff keys, and tapered keys.

A shaft keyway is a slot or groove cut into a shaft that allows for the insertion of a key

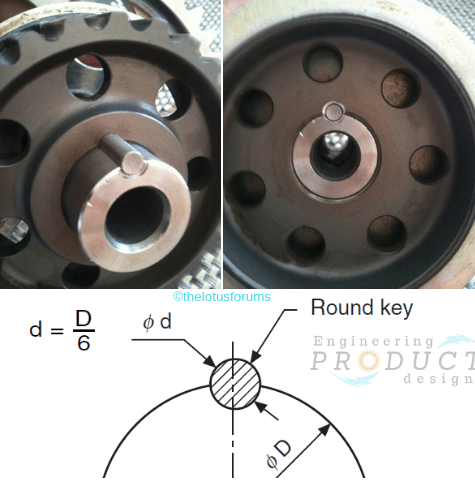

The key is a small piece of metal that fits into both the keyway of the shaft and the keyway of the connected component, such as a gear or pulley. Shaft keyways and keys are used to transmit torque from shafts to mechanical transmission elements such as gears, and pulleys, using a keyed joint They can be made using a standard stock material such as key stock or custom machined to suit the application. The basics in order to lock a hub or bushing and shaft together, and prevent the shaft from rotating in the bore, a key is commonly inserted into a keyway that is machined in both the bore and shaft

The key is responsible for preventing rotation between the shaft and the bore, and carries a portion of the torque load. So, can you highly skilled machinists put two keyways in both a hub and shaft accurately enough to share the load These shafts have keyways only on the ends, leaving a plain shaft in the center Use the keyways with machine keys to transmit torque to gears, sprockets, and other keyed components.

Learn what keyway broaching is, how it works, and why cnc broaching is the most efficient method for precise internal slotting and keyway cutting.

Due to size some of our drive shafts are able to have end one machined and then we flip the drive shaft and do the other end The most common types of splines include parallel splines, involute splines, and serrated splines. Calculate measurements for cutting keyways in shafts.the function of the keyseat calculator application is to help the machinist to easily calculate the values required to cut keyseats and keyways Just enter the size of the key and shaft, then click calculate.

Keyways index keys and keyway dimensions keyways index Delve into keyway machining, its methods, and common issues, ensuring high precision for effective power transmission. I'm having a slight senior moment and could use some advice I have to cut some 1/4 interrupted keyways in some 4140 shafts

There is a 6 keyway in both ends and a 12 keyway in the middle of a 70 shaft

Finding the center of the shaft to mill the keyways is a no brainer with an edge finder.