The Strategy Of Reliable Inventory Management At Industrial Supply Co Inc Accure Celebres 60 Years Mputer Insights

These machines allow for more control and security, and more accurate tracking of inventory and budgets. The most exacting processes require the most exacting measurements. Inventory management best practices are strategies and techniques used to optimize stock levels, reduce costs, and improve efficiency in handling inventory throughout the supply chain, including forecasting demand, tracking stock, implementing automation, and conducting regular audits.

Accurate Industrial Supply Co. Celebrates 60 Years – Computer Insights

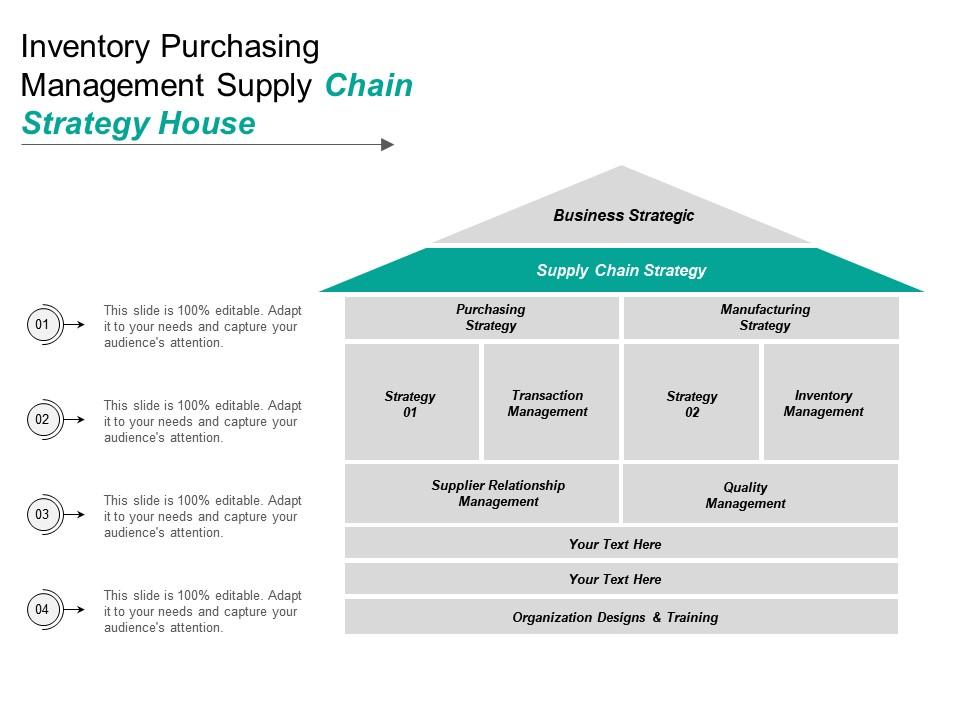

A quick summary and overview effective inventory management is crucial for supply chain success, impacting everything from operational costs to customer satisfaction It is a cornerstone of supply chain management and logistics in the material management system. Inventory management is the heart of supply chain management, encompassing all the processes and systems used to track and control a company's inventory

It involves balancing the costs of holding inventory against the benefits of having sufficient stock to meet customer demand.

Optimizing inventory management for industrial distributors Strategies for efficiency and profitability posted by strobels supply inc On mar 26th 2024 in the dynamic landscape of industrial distribution, effective inventory management stands as a cornerstone for success. Adapt to evolving business needs and market conditions

Effective inventory management is the backbone of a successful business operation By implementing these 11 practical steps, you can streamline your inventory management process, reduce costs, improve customer satisfaction, and ultimately boost your bottom line. Explore the essential practices of inventory management and optimization in this comprehensive guide This comprehensive guide explores 30 essential strategies and methods designed to revolutionise inventory management

Readers will discover actionable approaches to optimise inventory levels, minimise costs, and improve customer.

Because of this complexity, a sophisticated inventory management system is needed, tailored to production schedules and supply chain dynamics. A reliable inventory management system is essential for tracking stock levels, forecasting demand, and managing replenishment This comprehensive guide explores the critical components of inventory management in industrial engineering Learn about the challenges industrial engineers face, effective forecasting techniques, and the integration of technology in.

Bain & company is a top management consulting firm We advise leaders on strategy, marketing, organization, operations, it and m&a, across all industries and geographies. Is a leading north american distributor of a broad range of metalworking and maintenance, repair and operations (mro) products and services We help our customers drive greater productivity, profitability and growth with approximately 2.2 million products, inventory management and other supply chain solutions, and deep expertise from more.

But there are a range of strategies and methods you can deploy to improve inventory management

Read on to learn why inventory management is important, explore the key elements of creating your own inventory management plan, and get pro tips on how to optimize your inventory management plan. The strategies outlined above—from building relationships with suppliers to tracking spending data—can help industrial businesses optimize their supply purchases and save money over time However, the key to success lies in staying proactive, using technology to streamline purchasing, and consistently reviewing purchasing habits. An inventory management system is crucial for businesses seeking efficient inventory management

Inventory management is the act of ordering, tracking, storing and selling inventory across the entire supply chain Why inventory management is a strategic investment investing in inventory management for industrial parts supply goes beyond simply maintaining stock It ensures that equipment downtime is minimized, costs are controlled, and operational efficiency is maintained. Remember that every business is unique, so it's essential to tailor your strategic inventory management plan according to your specific needs and challenges

Stock replenishment is a critical aspect of inventory and supply chain management

Having enough stock means unimpeded sales, but having too much can create extra costs and inventory complications Abstract inventory is a central management function