How A Custom Pulley Designed By Ai Improved Conveyor Speed By 40 Percent Chin Fctory Steel Csting Motorized Drive Hed

Efficiency, speed, and precision are essential in modern manufacturing Selecting the right pulley, especially the drive pulley, can be complex. Ai maglev conveyor system, combining magnetic levitation (maglev) technology with artificial intelligence (ai), revolutionizes automated production processes

China factory Custom Steel Casting Motorized Conveyor Drive Head Pulley

This system reduces maintenance costs and downtime by eliminating friction, enhancing operational efficiency. The rpm of a conveyor belt calculator is an essential tool that calculates the rotational speed of the conveyor belt. In contrast, the ai maglev conveyor eliminates mechanical contact, cutting down on maintenance and downtime

This frictionless design enhances durability and ensures consistent performance

Adaptive ai control for dynamic loads one major innovation of the ai conveyor system is its intelligent routing. The integration of artificial intelligence (ai) into conveyor systems is becoming increasingly important as industries look for ways to enhance efficiency and streamline operations Edge devices—like sensors and motors—just followed instructions Ai allows conveyor systems to evolve from being command receivers to decision contributors.

Introduction to variable pulleys variable pulleys are an essential component in modern mechanical systems, offering flexibility in speed and torque adjustments They are designed to change the diameter of the driving and driven pulleys, which in turn adjusts the speed of the machinery Ai is revolutionizing conveyor systems in modern warehouses, offering unprecedented levels of efficiency, accuracy, cost savings, and flexibility As businesses face increasing pressures to deliver products quickly and accurately, integrating ai into conveyor systems is becoming essential.

Artificial intelligence (ai) has revolutionized many industries, including the manufacturing sector with its ability to automate processes, increase efficiency, and improve overall operations

One area where ai is making a significant impact is in conveyor system operations Conveyors play a critical role in the movement of goods and materials within a manufacturing facility, and ai technology. Robotics have notably been part of conveyor systems for decades However, companies are now gravitating towards ai.

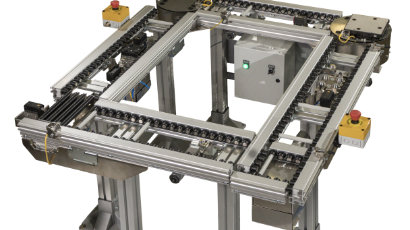

Key takeaways on trends in conveyor technology smarter automation Typical maximum conveyor belt speeds for products like grain and free flowing material mine coal and earth primary crushed hard ores and stone are indicated in the charts below: The design and implementation of pulleys, particularly head pulleys, play a crucial role in the efficiency and reliability of conveyor systems Recent advancements in pulley design, lagging technology, and structural reinforcement have redefined best practices for extending pulley life and improving conveyor reliability.

Many people don't realize how complex custom pulleys are—learn more about their various types, applications, and more in this blog.

Learn key considerations for effective conveyor belt drive pulley design to enhance system performance and longevity. How does the diameter of a pulley affect its speed Larger pulleys turn slower, while smaller pulleys turn faster, given the same input speed This relationship allows for speed reduction or increase in systems

What does rpm mean in a pulley system Rpm stands for revolutions per minute and indicates the speed at which a pulley or wheel is. Pulley maven is an online web based cloud computing program that greatly simplifies the problems and complexities associated with conveyor pulley design & analysis Andrew hustrulid has worked on or around pulleys for the last 2 decades and this is the program he wanted but it did not exist.

Custom timing pulleys custom pulley drive systems for power transmission applications while standard components often meet general power transmission needs, unique challenges sometimes require a custom solution

Sdp/si offers expert engineering and precision manufacturing for custom pulley systems tailored to your exact specifications. An internationally recognized conveyor belt manufacturer, fabricator & distributor offering rubber conveyor belts, plastic conveyor belts, & belt pulleys. Properly designed pulleys ensure the reliability and longevity of conveyor systems, minimizing downtime and maintenance costs This blog post aims to provide a foundational understanding of conveyor belt pulley design, covering essential principles, key considerations, and advanced techniques.

This document contains calculations for determining the speed and throughput of a conveyor system It lists specifications of the conveyor components like motor speed, pulley diameters, gear ratios, sprocket sizes Given a motor speed of 960 rpm, conveyor length of 60m, and 2 decks, it calculates the final shaft speed, linear speed, retention time, and throughput of 15.35 mt/hr Custom pulleys offer many benefits across industries including mining, manufacturing, and food processing, from increased traction to better belt alignment and improved durability.

Shop standard & metric precision pulleys to request a quote for conveyor pulleys, idlers or friction drive rollers designed for many industrial applications.