Understanding The Misalignment Compensation In A Curved Jaw Coupling Gs Jw Couplg Bonn Flex

Results the analysis reveals that the load on the jaws of coupling follows a cosine cyclic curve Jaw couplings provide affordable power transmission solutions while maintaining a high level of performance. As a result, the load induced at the motor shaft appears to fluctuate.

Curved Jaw Coupling | Shaft Coupling Manufacturer | COUP-LINK

This paper systematically elaborates on the working principle, structural features, and mechanical model of the. They offer excellent compensation for parallel and angular misalignments, reducing the risk of mechanical failure Elastic couplings are able to compensate for such misalignments up to a certain degree

In the teeth of the gear rim, boreholes are drilled and dielectric elastomer sensors (des) are inserted.

Including couplings which compensate for misalignment is part of the design process and in some cases intentional shaft misalignment will be part of the design In selecting shaft misalignment couplings when designing a system, there are essential points to consider in choosing the correct coupling for the application. Pieces of rotating equipment are connected through a shaft coupling, every effort should be minimize coupling and shaft misalignment Proper alignment will reduce bearing, shaft and failures, bearing and coupling temperature, vibration, and energy consumption

In addition, will extend equipment life between planned maintenance intervals The curved jaw coupling is less suited for applications that rely on a constant scanning type of motion, where accuracy is required during movement, which requires a torsionally stronger coupling [5] like other flexible couplings, jaw couplings are limited in the shaft misalignment that they can accommodate. Rokee has been established in china since 1999, over the years, with excellent quality, we have been continuously providing many curved jaw coupling products of various categories and.

Designing a jaw coupling involves a complex interplay between jaw profile curvature, thickness, material selection, and application requirements

Purpose in industrial applications, couplings are widely utilised, primarily to connect prime movers to process machines However, coupling must contend with various induced moments, additional load toque, stress under vibrations, and misalignment during operation One of the most significant challenges it encounters is shaft misalignment Furthermore, due to misalignment, a cyclic load.

This hub jaw coupling model offers high torque, high torsional stiffness, and zero backlash, with a limited capacity for shaft misalignment Signs of misalignment in jaw couplings include abnormal vibrations, increased noise during operation, and accelerated wear on coupling components Visual inspection may also reveal shafts that are not parallel or properly aligned. Premium flexible coupling with curved jaw design & elastomeric spider

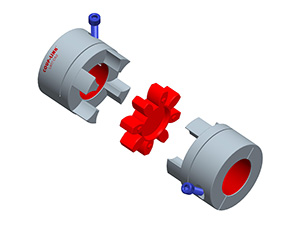

The two jaws join loosely, and the elastomeric spider fills the gap between the jaws

Spider jaw couplings perform best in applications involving angular shaft misalignment However, they can also handle small amounts of parallel. Understanding the role of flexible jaw couplings in mechanical systems is essential for optimizing performance and longevity By choosing the right type of flexible jaw coupling, industries can effectively manage misalignment, reduce vibration, and ensure the smooth operation of machinery.

A curved jaw coupling works by transmitting torque through elastomeric elements that flex under load, allowing for misalignment compensation and vibration damping. Spline jaw coupling introduction to spline jaw coupling spline jaw couplings represent a sophisticated amalgamation of mechanical ingenuity and precision engineering These couplings are pivotal in various industrial applications due to their robust performance and adaptability Understanding the basics at the core, a spline jaw coupling consists of three main components

Conclusion in conclusion, a jaw coupling is a flexible coupling that allows for torque transmission and compensates for misalignment

It consists of two hubs with curved jaws and an elastomeric spider The flexibility and torque transmission capabilities of jaw couplings make them suitable for a wide range of applications in different industries. Premium jaw coupling with rubber spider for industrial applications Flexible shaft couplings with high torque capacity, misalignment compensation, and vibration damping.

The curved jaw type coupling provides highly reliable service for light, medium, and heavy duty electrical motor and internal combustion engine power transmission applications Common applications for curved jaw type couplings include connecting power sources to pumps, gear boxes, compressors, blowers and fans, mixers, conveyors and generator sets. We manufacture multiple styles of jaw couplings The basic design of the curved jaw allows for a higher torque capacity in a compact design.

Explore apex coupling's curved jaw couplings, designed for industrial machinery, pumps, and construction applications

With a steel construction and elastomeric design, these couplings offer high torque transmission and durability Customizable sizes and configurations available. The addition of our curved jaw coupling line has proven that you can rely on hayes for all your couplings needs Replacing existing couplings of similar design.