Fully Automated Cnc Systems To Process Data Directly From Keyway Charts Wood Cutting Sck Pho 1721196037 Shuttersck

Siemens machine tool systems supports you as a partner in increasing manufacturing efficiency in the best possible way Cnc automated machining reduces costs and production times and enhances safety, quality control, and sustainability Machinemetrics has simplified iot machine monitoring for the shop floor

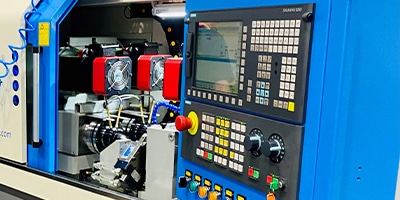

Fully Automated Cnc Machining Turning Milling Stock Footage Video (100%

Automation in cnc machining automation in cnc (computer numerical control) machining refers to the integration of advanced technologies that enable machines to operate with minimal human intervention Delve into keyway machining, its methods, and common issues, ensuring high precision for effective power transmission. From loading and unloading parts to fully automated production systems.

Benefits of automated production processes with the automation of cnc machines, companies are able to utilize their production to the maximum

This reduces throughput times and gives the staff freedom and flexibility to carry out qualified. Boost efficiency and precision with effortless connectivity and insightful analytics. Automating cnc workflows from design to delivery a Cad/cam ai integration modern cam software suggests optimal strategies based on part geometry and machine capabilities

Mes (manufacturing execution systems) systems like shopflooriq or tulip provide job tracking, order. Explore how comprehensive process automation in cnc machining sectors revolutionizes manufacturing efficiency, accuracy, and operational excellence Application process and required technologies of autonomous cnc systems autonomous cnc (computer numerical control) systems offer advanced automation, data integration, and continuous improvement solutions compared to traditional cnc machines Their integration into industrial production processes provides significant gains in efficiency, flexibility, and quality

Fully automated factories are considered to be the future of the manufacturing industry

This guide explores key information and developments. Cnc milling and machining solutions cnc, or computer numerical control, machine tools utilize programmed computer software to automate the control, movement and precision of the cutting process Cnc milling machines are used in many manufacturing industries, including aerospace, automotive, construction and medical devices. Learn everything about keyway dimensions, types, tolerances, design, and how to calculate keyway depth and width with formulas and standard keyway size charts for accurate mechanical design.

The cnc machining automation guide begins by defining cnc machining automation as the use of automated technologies and control systems to handle machine tools and processes in manufacturing. Working principles cnc slotting machines operate using a reciprocating motion of the ram, which is guided by the cnc system This ensures that the cutting process is precisely controlled, resulting in accurate and repeatable keyway. Check out the lock keyway types (best, schlage, etc.) and designs, the difference between schlage and kwikset, as well as what is a keyway.

Highly efficient cnc bending technology for small and big bending tasks with the greatest precision

Our fully automated solutions mean optimum cycle times and large production volumes The outstanding flexibility of our advanced cnc tube bending machines gives you economical bending process and meets the most demanding requirements.