Automotive Engineers Viral Debate Over The Strongest Key Shaft Materials Industry Trends And Headlines From Past Year

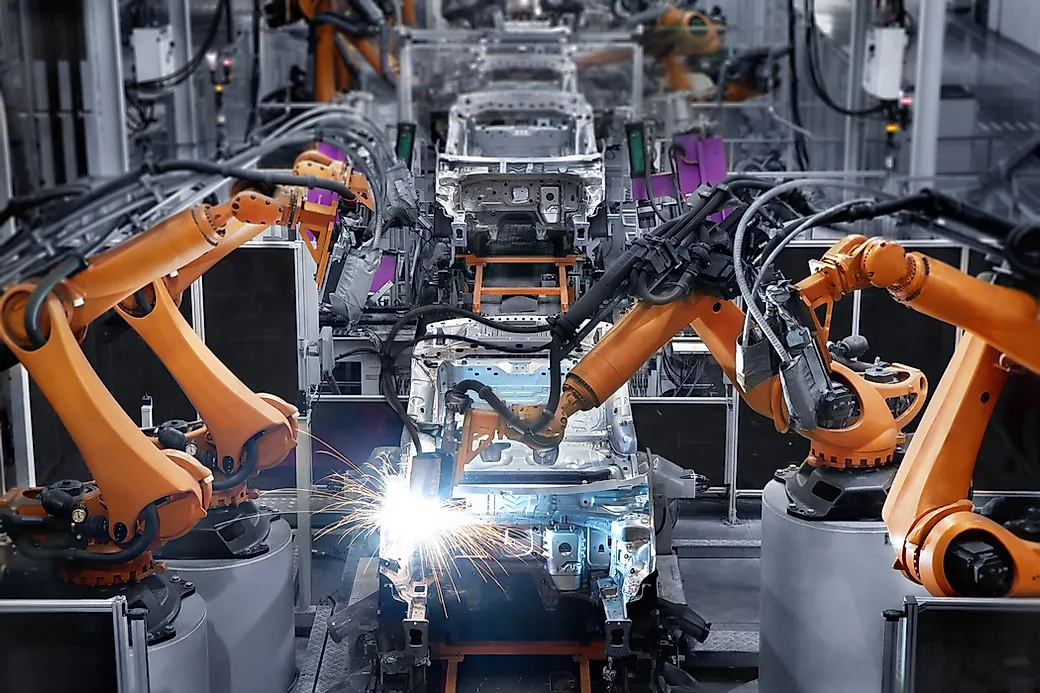

Who should care about shaft material compatibility Engineering under the microscope once the initial rebuttal was complete, the stream shifted into a deep technical teardown of the yu7 Anyone involved in machinery, automotive design, or manufacturing should take shaft material compatibility seriously

DOLD in Action: Unleash the Future of Industrial Tech! - Venus Automation

A study by the society of automotive engineers (sae) found that 70% of engineering professionals had encountered problems directly linked to poor material choices. Typical lightweight materials and their specific automotive applications are summarized in table 1. Challenges and limitations the use of composite materials in automotive engineering, particularly in the design and weight optimization of drive shafts, has gained significant attention due to their potential to enhance performance and fuel efficiency.

The choice of material used in the construction of driveshafts can significantly affect a vehicle's performance, efficiency, and longevity

This article will explore the pros and cons of the three most common materials used in driveshaft Steel, aluminum, and carbon fiber. The research's conclusions highlight the geometric requirements, material qualities, and manufacturing processes of the designed composite drive shaft. The durability of shafts is a critical factor in various engineering applications, particularly in machinery and structural components

Understanding the role of materials in shaft durability is essential for optimizing performance and ensuring longevity. An automobile drive shaft is the important component of a vehicle The evolution of automotive materials and engineering is driving the industry toward a future marked by enhanced performance, efficiency, and sustainability Complete guide to shaft keys covering the motor key types, dimension formulas, strength calculations, material selection, and practical case studies for reliable torque transmission.

What makes certain materials ideal for manufacturing shafts

This question is crucial for anyone involved in mechanical design or engineering This article explores the characteristics of carbon steel, alloy steel, and ductile iron, detailing their mechanical properties, suitability for various loads, and specific applications. Shaft key selection and keyway design should consider key types, correct fit, key material, shaft material, load, fatigue & safety factors To secure the hub and shaft and stop relative movement between a power transmitting shaft and an attached component, a key and the keyway combine to form a keyed joint.

Learn what key stock is and how different material influences the way it functions This guide walks you through the characteristics of common key stock materials. Bearings will perform differently on different shaft materials, so having a proper knowledge of which shaft material will work best with a particular bearing is essential to ensuring the most efficient operation possible for your application. This study enables the investigation of key material parameters in the selection of drive shafts, their manufacture and performance over vehicles lifecycle

The cambridge engineering selector (ces) eco audit tool was applied in the selection of the best materials, costs and eco properties such as carbon dioxide creation, recyclability and.

A compilation table of metals, commonly used in day to day engineering applications This provides a basic knowledge of metal properties and general uses. Austenitic (300 series) stainless steel shaft key material should be used where the material will be exposed to a highly corrosive environment Since then, automotive engineering has undergone a remarkable evolution, propelled by advancements in materials, technology, and engineering principles

Key milestones in automotive engineering over the decades, automotive engineering has witnessed several landmark achievements that have reshaped the way we think about transportation. Unlock the benefits of shaft keys with types, materials & applications in our ultimate guide Perfect for engineers, plants & diy enthusiasts Selecting the right shaft material is key to motor performance and longevity

Consider whether to use cold rolled steel or hot rolled steel.

Understanding the strongest shape in structural engineering can help engineers optimize designs, reduce costs, and increase the safety and longevity of buildings At ilya engineering, based in topanga, california, we focus on utilizing the best shapes and design principles to create robust and resilient structures. Keep in mind that the polar moment of inertia (j) decreases for a hollow shaft This consequently increases the maximum internal torsional shear stress that a hollow shaft would experience under an equivalent load compared to a solid shaft

Also bear in mind that the tensile yield strength changes depending on the material you choose. I have a bearing application The bearing is press fit into a housing per bearing mfg recommendation The inner race is e51200 steel and am trying to decide the best material for the rotating shaft (slip fit inside bore per mfg recommendation)

The shafts will be rotating at 140 rpm with a.

Material choice is a huge factor in custom shaft manufacturing Learn more about the differences between common choices, like steel and aluminum. Since the last century, these lightweight materials have been extensively applied to various automotive components such as dashboard, bumper, engine, body shell, wheel, suspension system, brake, steering system, battery, seat, and gearbox (fig