Facility Managers Viral Photos Of Properly Aligned V Belt Sheaves And Sheaes Mtsindustrial Com

Proper alignment ensures smooth power transmission, longer belt life, and optimal machine performance Ideally, you want to have both parallel and angular harmony. Angle regular inspection and maintenance to ensure proper alignment, correct tensioning, and prompt detection of signs of abnormal wear are needed to keep a drive performing as it was designed

V-belts and Sheaves | mtsindustrial.com

Poor design poor drive design. Misalignment can take either the form of angular or parallel (offset) misalignment, or a combination of both Depending on the severity, misalignment reduces belt performance by increasing wear and fatigue

A belt can be worn out within a matter of hours or days if the belt drive has been aligned incorrectly

Basically, any degree of misalignment angular or parallel will decrease the normal service life of a belt drive. Learn the common causes of belt failure and wear misalignment, improper tension, contamination, and wear plus practical steps to extend belt life. Sheave wear belt wear proper belt and sheave sizing photo courtesy of browning checking for sheave wear sheave wear is most often caused by sheave misalignment Using the proper size of groove gauge (along with a flashlight), mechanics can check for sheave wear

If wear is present (see photo), the sheaves should be replaced, and properly aligned. Gain insight from industry experts to keep your equipment running smoothly and efficiently. Pulley alignment there are many different factors that contribute to machine downtime when considering sheave/pulley, belt and bearing wear The single biggest factor that can impact the reliability of belt driven equipment is pulley alignment

Just a few minutes of intentional pulley alignment can lead to extended service life

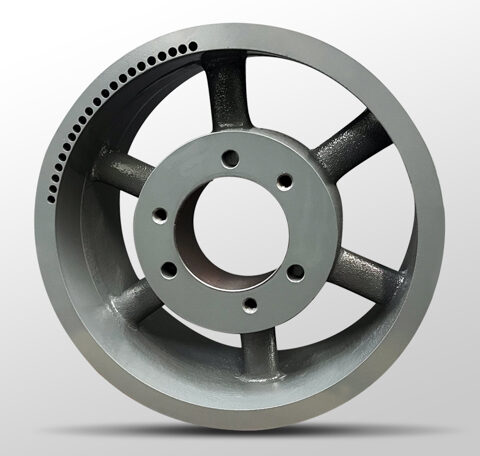

Depending on its severity, misalignment can gradually reduce belt. It is recommended to check and adjust belt tension under full load after 20 minutes, 24 hours, and 48 hours of operation to properly seat the belts in the sheave grooves. Stock sheaves have capacities ranging from 1/2 to 108 Models offered in four types for use in a variety of tough applications including aggregate and oilfields.

Sheave alignment the last factor in belt maintenance we want to cover is sheave alignment One crucial but often overlooked aspect of machine maintenance is sheave alignment. We craft our sheaves and bushings to exceed the stringent astm/sae specifications for gray iron casting. Groove angles and dimensions for sheaves and the face widths of sheaves for multiple belt drives are given below, along with various tolerance values

Where n g is the number of grooves.

Sheaves and sprockets should be checked for proper alignment A laser alignment tool is the recommended means Most major belt manufacturers recommend a nominal tolerance of 0.5 degrees However, better alignment tolerances should be achieved if possible

The table below can be used to determine proper alignment. A related problem, uneven belt and cord loading, results in unequal load sharing within multiple belt drives, and can lead to premature failure.