Bearing Snap Ring: 2026 Design Innovation Prevents Motor Vibrations 2000 Infiniti I30 Coupe Sedan T Pack Wheel Ring Wheel

Discover everything about snap rings (retaining rings) in this ultimate guide Suitable locating bearings a double row angular contact ball bearing, for example, will give closer axial guidance than a deep groove ball bearing or a spherical roller bearing. Learn about types, installation, removal, materials, and applications for industrial and automotive use.

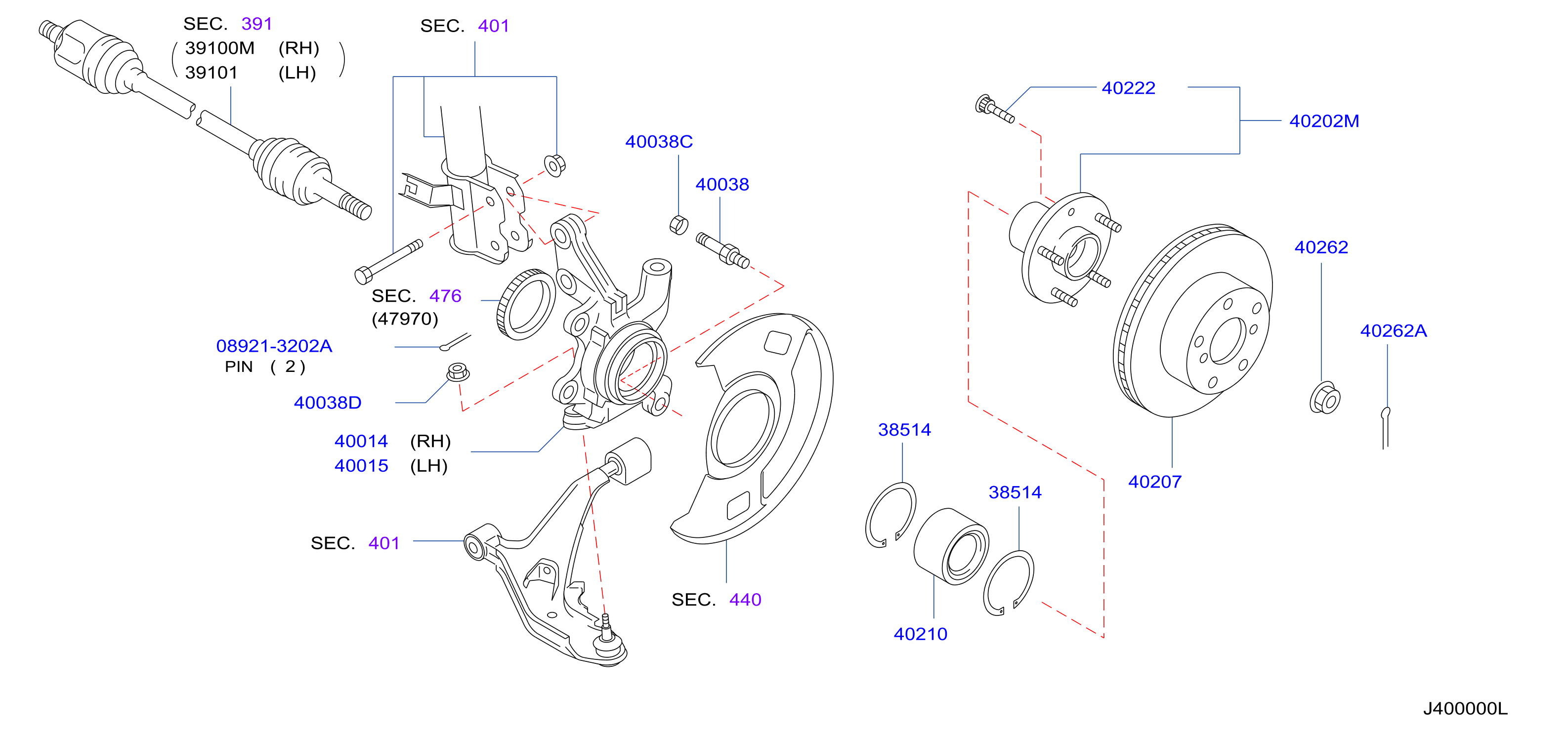

2000 Infiniti I30 Coupe SEDAN T/PACK Wheel Bearing Snap Ring. Wheel

Installation and removal best practices proper installation ensures performance and longevity. The type of bearing selected as a locating bearing depends on the magnitude of the axial forces and the accuracy with which the shafts must be axially guided Beveled retaining rings enhance various applications, including transmissions, securing gears, and bearings

By evenly distributing loads and preventing axial movement, they ensure smooth operation even under high torque and rotational speeds, which helps reduce noise and vibration and extends bearing life.

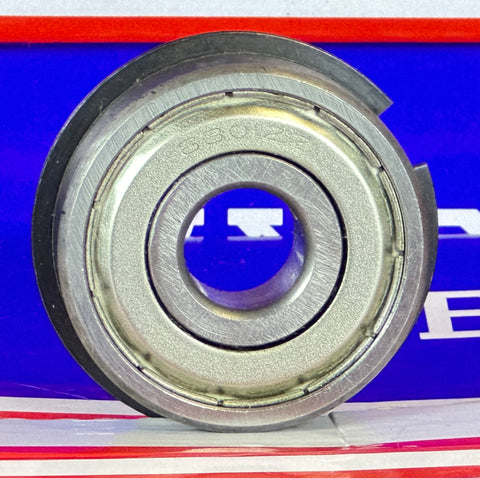

A snap ring is defined as a retaining device that can be used for axial location of rolling bearings, providing benefits such as space savings and simplified mounting and dismounting It is typically positioned in a groove and may require an abutment collar to withstand heavy loads Ai generated definition based on Manual of engineering drawing (third edition), 2009

Discover the essentials of retaining ring design calculation in this comprehensive guide Learn sizing, material selection, and stress analysis for optimal performance. Get expert insights into the world of snap rings, covering design principles, selection criteria, and application best practices for optimal mechanical system performance. Retaining rings, also referred to as snap rings, primarily provide shoulders to locate or retain parts on shafts or in cylinders

Advantages of retaining rings are their economy of manufacture, ease of assembly and accuracy of positioning as compared to threaded fasteners.

By providing a reliable means of retention, snap rings contribute to the operational efficiency of machinery, helping to maintain consistent performance over time Vibration analysis techniques vibration analysis is essential for monitoring the condition of deep groove ball bearings. Vibrating machines represent some of the most challenging applications for bearings Spherical roller bearings for vibrating applications offer reliable operation across a broad range of applications.in applications inducing vibrations, such as shaking screens, road rollers, exciters, vibrating engines and planetary gearboxes, acceleration levels and speeds are generally high and lubrication.

Based on this standard, it can be determined whether the motor meets the requirements The hazards of motor vibration the motor generates vibrations, which can shorten the insulation and bearing life of the winding, affect the normal lubrication of the sliding bearing, and cause the insulation gaps to expand due to vibration forces. Motor vibration disrupts operations and damages equipment Learn causes like misalignment, imbalances, and solutions like monitoring, alignment, and balancing.

Behrooz parhami's blog & books page page last updated on 2025 december 31 this page was created in 2009 as an outgrowth of the section entitled books read or heard in my personal page

The rapid expansion of the list of books warranted devoting a separate page to it Given that the book introductions and reviews constituted a form of personal blog, i decided to title this page blog & books. Sealing devices sealing devices not only prevent foreign matter (dirt, water, metal powder) from entering, but prevent lubricant inside from leaking If the sealing device fails to function satisfactorily, foreign matter or leakage will cause bearing damage as a result of malfunction or seizure.

Unfortunately though, many bearings fail prematurely in service because of contamination, poor lubrication, misalignment, temperature extremes, poor fitting/fits, shaft unbalance and misalignment All these factors lead to an increase in bearing vibration and condition monitoring has been used for many years to detect degrading bearings before they catastrophically fail, with the associated. To prevent this, use precision instruments such as the skf shaft alignment tool and microlog vibration analzer to check alignment and vibration, and the appropriate tools and methods when mounting bearings Insufficient bearing load bearings always need to have a minimum load to function well.

A snap ring is a special form of locking ring

In mechanical engineering, it secures components such as wheels, sealing elements and bearings on axles, shafts or within bores against axial displacement with a positive fit. Rolf hoppler and reinhold errath evaluate the types of bearings used in the cement industry, of ering their hints and tips for avoiding problems with lubrication, greasing, motor cabling, installation, alignment, bearing currents, temperature and vibration. Select your mopar model below to shop for more parts from its entire oem parts catalog. Lock washers are designed to prevent bolts from vibrating loose by creating tension in the assembly

These washers typically feature a split or serrated design that grips both the bolt head and the surface of the material being fastened