Precision Reveal: How Taper Lock Hubs Prevent Shaft Slip In Heavy Industry Hub

These keyless locking devices use a tapered design to create a strong frictional grip between shaft and hub, ensuring a secure, concentric connection every time. Dst bushings provide the highest torque carrying capability The tapered design ensures that the bushing grips the shaft tightly, preventing any slippage during operation

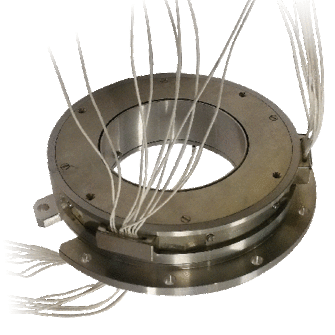

Taper Locks | Taper Lock Hub | Taper Lock Hubs

This secure fit is crucial in applications where precision and reliability are very important, such as in manufacturing processes where consistent performance is essential. The external key ensures a secure connection without applying force to the cap screws The hub may also include keyways or splines to provide additional torque transmission capabilities and prevent slippage

Tapered bushing the tapered bushing is inserted into the tapered bore of the hub and mounted onto the second shaft

It is designed to securely grip the shaft and transmit torque from the hub to the shaft. Conclusion taper lock bushes are essential in ensuring the smooth operation of mechanical systems From improving power transmission to simplifying installation and protecting shafts from wear, the benefits are clear Choosing the right taper lock bush plays a critical role in the overall efficiency and reliability of your equipment.

The values assume that the assembly uses a fenner taper lock bush fitted, in accordance with the instructions supplied with every bush, to a hub prepared to the fenner specification Slip will tend to occur at the bush/shaft interface, at the prescribed torque, unless a key is fitted. Axial loads applied to the locking devices are translated into radial loads that clamp the gear, pulley, or other component to a shaft. Taper lock bushes are designed to link the shaft to the sprocket or pulley mechanically

It is correctly fastened to the shaft via its conical surface using the matching component

This makes the primary element versatile enough to work with various shaft sizes The keyway and thread of the taperlock bush are machined to iso specifications If you are unfamiliar with the mechanical benefits of. Bearing lock nuts are popular options if you can cut threads in the shaft

Interference fits are very common, but obviously require you to be able to heat the bearing and/or cool the shaft to get them put together Shaft spacers combined with a keeper plate would work as. Motion stocks taper lock type bushings, filtered by bushing size, bore type, material, and more Short key ‡ 3/4 3/4 1 1/16 1 1/16 1 1/16 1 1/16 1 1/16 1 3/8 1 5/8 1 5/8 2 1/16 2 1/16 ø for general reference

Severe conditions may require larger hub

Hub diameter required depends on the particular application Consult martin giving full information on the proposed design. When a shaft is mechanically joined to a sprocket or a pulley, taper lock bushes are the type of bushing that is deployed Through the tapered surface of the component, it is securely attached to the shaft, which matches the component

The taper lock bushes offer flexibility between the primary components, making them appropriate for use with various shaft sizes Four digits, each of which. Discover durable stainless steel taper lock bushings suitable for wastewater, agricultural, and food & beverage industries Order from our extensive inventory today!

Choose from our selection of shaft locks, including clamping shaft collars, set screw shaft collars, and more

Same and next day delivery. They accept compatible type and series bushings and provide optimal shaft engagement for power transmission components. The thick split spider on these couplings takes on twice as much torque as standard split spiders, while a set screw holds the hubs in place on your shaft Units are available in both inch and metric bore sizes and are made in the usa.

Stepped shafts require machining, but offer higher precision in shaft positioning and better axial load carrying capability The common locking method for stepped shafts is to use a cylindrical bearing seat and an interference fit between shaft seat and bearing inner ring, and a lock nut to secure the bearing axially. In addition, our sh bushings withstand heavy loads (for both torque and axial forces), and extremes of temperature. These bushings are designed with keyways that align and lock into place on both the shaft and the hub