Understanding The Polymer Blending Process In Modern Gates Drive Belts Plastic Ress Star Plastics

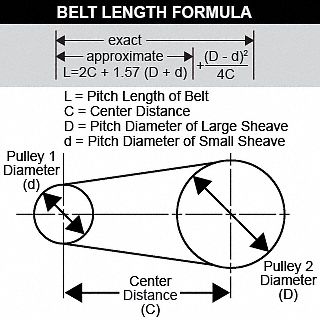

Belts also weigh less than their chain counterparts. A quick, four step process of entering drive details provides all possible gates tpu belt recommendations for your operation so you can level up your existing belt drives or create your next system today. The latest innovations in gates synchronous drive systems are two redesigned and reengineered belt and sprocket lines

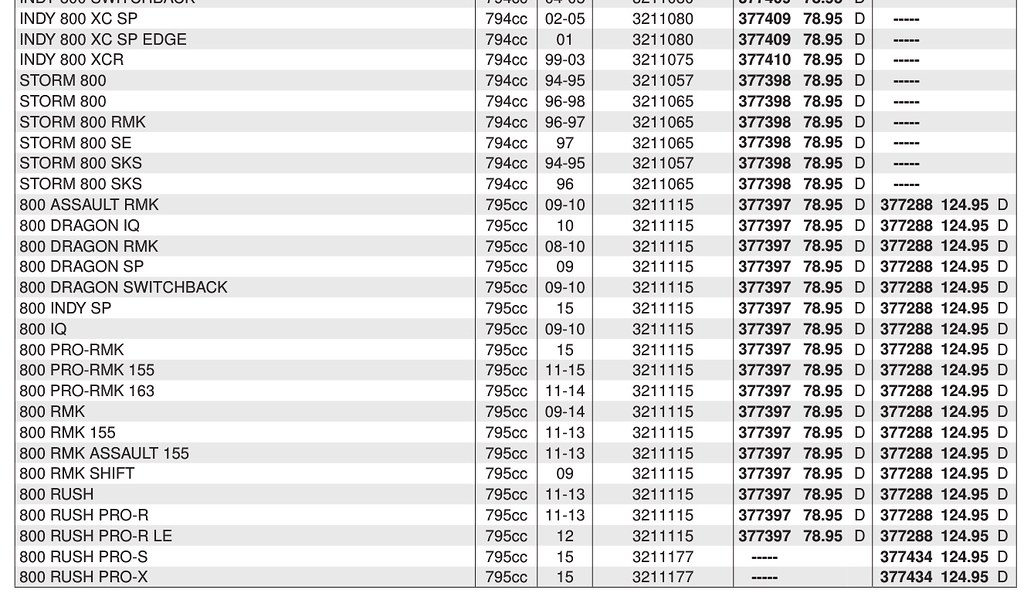

Gates Drive Belts Size Chart | Paul Smith

They are the clear winners in overall cost, drive selection options and performance when compared to any other belt drive products on the market today. Contains detailed information for each part, 360 images, dimensions, diagrams, technical videos, bulletins and installation tips. The solution was a gates poly chain® gt® carbon® belt drive system, at about 1/3 the cost of the replacement gears, and an anticipated installation time of half a day.

Polyurethane synchronous belt with patented carbon tensile cords through providing you with precise drive solutions of unsurpassed quality and leading edge technology gates brings you the ultimate in synchronous drive systems

Poly chain® gt carbontm is gates' newest polyurethane synchronous belt with patented carbon tensile cord design suited for high torque, low speed drives The enhanced uniformity achieved through belt press technology translates to improved material performance, reduced defects, and greater reliability in the final products, making it an invaluable tool in the arsenal of modern polymer processing techniques What role does temperature control play in belt press polymer mixing Temperature control is a critical aspect of polymer mixing, and the.

And any speed in between Gates has your total synchronous belt drive system solution Synchronous belt drives are being used more extensively than ever for the transfer of power from one shaft to another, multiplication of torque,speed reduction or increase, and synchronization of shaft operations. Importance of polymer blending in modern industries polymer blending plays a crucial role in modern industries, enabling the creation of materials with specific properties, such as high strength, low weight, and resistance to chemicals and temperature fluctuations.

Timing belt backings does your application demand polyurethane belts tailored for specific performance needs

Gates materials science innovation allows us to offer the broadest range of belt drives for the most demanding conditions Our comprehensive line of belts is designed to improve reliability, and efficiency, while maximizing performance and ensuring long life. 🚴♂️ understanding gates belt drive technology what is a belt drive system Definition and components a belt drive system consists of a belt, pulleys, and a tensioning mechanism

Unlike traditional chain systems, which rely on metal links, belt drives use a continuous loop of reinforced rubber or polymer. Gates corporation delivers premium power transmission and fluid power solutions, including belts, hoses, and hydraulics for automotive and industrial use. Polymer mixing solutions are essential for optimizing belt filter press performance, significantly enhancing flocculation and solids capture in the dewatering process What are polymer mixing solutions and why are they important?

The gates industrial power transmission product catalog features information on gates industrial belts, metals, tools and accessories

The catalog includes comprehensive product overviews, specifications and application service descriptions. Explore the critical role of drive belts in vehicles 🚗 learn about types, functions, maintenance, and common issues to boost your automotive knowledge As we transition into the main content of this article, it's important to understand that the effectiveness of a belt filter press is heavily dependent on the quality of polymer preparation

Provides easy access to identify gates oe quality parts fitting your vehicle, anywhere around the world