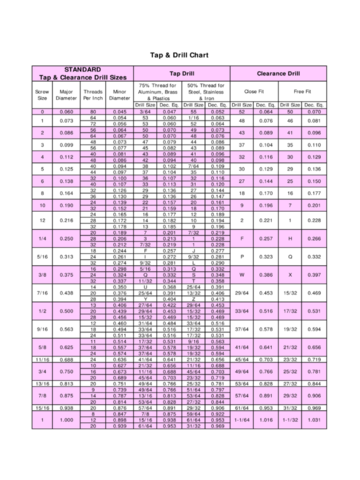

Analyzing The Material Removal Strategy When Using A 10-24 Tap Drill Size Tp Chrt For Stndrd Threds Tp 44% Off

Learn practical steps such as testing the fit, maintaining drilling technique, checking alignment, and exercising patience for strong, reliable connections in woodworking or metalworking projects. Using the wrong size can lead to stripped threads, a loose fit, or, in the worst cases, complete. By using a #7 drill bit at 0.173 inches, you ensure optimal engagement and reduce the risk of damaging your materials or tools.

Printable Tap Drill Size Chart Free [PDF]

Spiral flute taps pull chips out Selecting the correct drill bit size is paramount Form taps create threads by deforming material instead of cutting it

Choose the right tap for the job

Summary choosing the right tap drill size isn't hard It just takes a little planning Use charts, calculators, and test runs to get the best results The right drill size is the first step to threads that.

The tap drill size depends on the thread type and diameter Using the right tap drill size helps you get the best core hole sizes, dimension,s and strong threads. However, by using a few simple formulas and guidelines, it's possible to determine the optimal drill size for a given application. If the drill bit is too small

The tap will have to remove too much material

This dramatically increases the torque required and will almost certainly lead to the tap. Drawing from numerous diy projects, i'll provide you a concise guide to help you understand and apply this correctly. Follow practical tips for successful tapping, including tap alignment, lubrication, steady tapping, securing the workpiece, monitoring depth, cleaning threads, practicing patience, and testing fit for optimal results. Tap size is critical because it determines the compatibility with screws or bolts and the strength of the thread

There are also different types of taps, including hand taps and machine taps, each designed for specific applications and materials. Drill guides choosing the correct drill bit size for tapping threads is crucial for any machining or fabrication project A seemingly small detail like selecting the wrong drill bit can lead to significant problems, ranging from stripped threads and broken taps to compromised structural integrity and costly rework It's crucial for ensuring the integrity and safety of the final product

In today's projects, where precision and quality are paramount, using the correct drill bit size is not just a best practice, but a necessity.

Read this article to discover the exact drill size you need for this type of tapping operation. You can learn more about thread depth in tapping here To get the tap drill size in other depths, use our tap drill size calculator. You can always use a scrap of material to test the drill bit to make sure you are on the right track.

In this section, we'll explore the relationship between drill bit sizes and tap compatibility, focusing on the 1024 tap What is a 1024 tap A 1024 tap is a type of tap designed for threading small holes in materials such as metal, plastic, or wood. This provides a good balance between thread engagement and reducing the risk of breaking the tap.

Using the correct drill bit size prevents issues like stripped threads, ensures a secure fit, enhances project efficiency, and optimizes thread depth.

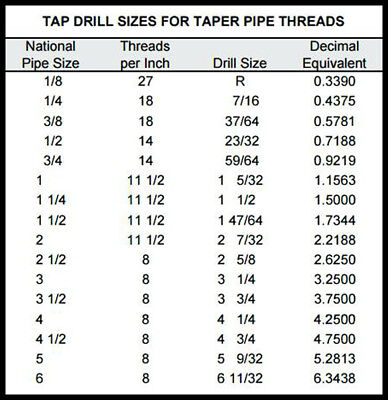

Therefore the tap drill chart is extremely important To create a thread properly, one would need a set of three taps that correspond to the same bit size Namely the bottoming, the intermediate, and the taper tap It is meant for fractional, metric, and screw sizes

Customers will be able to buy the right kind of hardware by analyzing the tap drill size The fractional sizes are listed in inches, while the metric sizes are listed in millimeters following the letter 'm'. The tap drill size of a hole that will be cold form tapped is usually bigger than it cutting tap counterpart (77% thread is what you want to use) a 100% thread is 3/4 qtr, or (6/8 th), of the full 60° triangle which is the maximum allowed height of a full thread, the v shape, including flats.

Unit conversion calculator to convert the following units acceleration, area, torque, electrical, energy, force, force / length, length, light, mass, mass flow.

Match the bit's diameter with the tap's major diameter for flawless results Find additional tips in our article to guarantee precision, including using a drill and tap chart, checking thread engagement, considering materials, and testing on scrap before tapping. The accuracy of your drilling process directly impacts the success of your project

![Printable Tap Drill Size Chart Free [PDF]](https://www.typecalendar.com/wp-content/uploads/2023/01/Tap-Drill-Charts-300x225.jpg)