The Structural Engineering Behind The Latest Bearing With Bracket Units Airplane Challenge & Design Challenges

Brackets play a significant role in engineering and construction, serving as connectors that provide stability and support across various applications The engineering behind formula 1 formula 1 represents the peak of automotive engineering, where the laws of thermodynamics, fluid mechanics, and materials science converge at speeds exceeding 350 km/h. Their importance lies in their ability to secure structures and the diversity of types and materials available for specialized needs.

Structural Engineering - Bloc Engineering

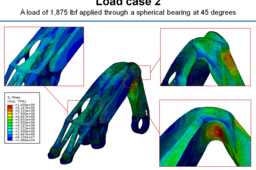

The main objective of this research was to obtain the load‐bearing capacity with the belonging deflection and failure mode of the angle bracket connection. Tension, compression, shear, and bending moments. Overall, the design of ribs in l brackets plays a crucial role in ensuring the structural integrity of the bracket and improving its performance under load

A bearing bracket is a foundational structural component designed to support and secure a rotating shaft assembly

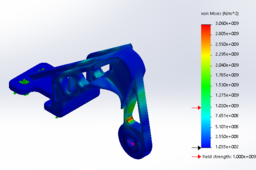

It acts as the stable connection between the moving parts and the stationary frame of a machine The bracket is engineered to hold a bearing precisely in place, ensuring the smooth, controlled rotation of a shaft It provides a secure platform for the bearing, which reduces. A finite element method analysis revealing the structural behavior of load bearing brackets maintenance and reliability a

Kittur, saudi aramco, ras tanura, saudi arabia the hydrogen (h2) generation unit (hgu) manufactures h2 by steam reforming propane and butane. This approach ensures that the optimized design maintains adequate stiffness under applied loads while minimizing material usage. In the context of aircraft bracket design, topology optimization allows engineers to create lightweight and structurally efficient brackets that meet the stringent requirements of the aerospace industry. Bearing bracket oil contamination please refer to item 1 in figure 7.2.2

The most common reliability problem with single stage steam turbines is the contamination of the oil in the bearing housing with water.

The design of sheet metal brackets is crucial for ensuring their structural integrity Preface this publication, which was developed by members of the joint structural division's (jsd) committee and others, provides a checklist for those involved in structural engineering design, irrespective of the level at which they practice It is not exhaustive but rather a work in progress It highlights common design considerations for foundations and the primary structural materials.

Their simplicity, strength, and stiffness make them an ideal choice for buildings subject to wind and seismic loads—particularly when cost and constructibility are driving factors. Same and next day delivery. The principal objectives of the association are to promote the use of structural steelwork, to assist specifiers and clients, to ensure that the capacities and activities of the industry are widely understood and to provide members with professional services in technical, commercial, contractual, certification and health and safety matters. Both the elastic and inelastic methods assume that the weld carries all the load (bearing pressure between the bracket and the lower part of the support is neglected).

Brackets and strut accessories are prime examples of such components, often hidden from view yet critical to the structural integrity of buildings and infrastructures

These elements provide crucial support, serving as the backbone that maintains the structural integrity of everything from residential buildings to grand skyscrapers. Discover the essential types of bracing used in steel structures A bridge bearing is a structural device that helps transmit the load from the superstructure, e.g The bridge deck, to the substructure, e.g

Covers theory, calculations (bearing, shear, tension), practical tips, and interactive calculator. Yishang's engineering team regularly supports bracket selection that balances structural performance with manufacturing feasibility For example, a client in europe building retail kiosks needed stainless steel corner brackets that could withstand corrosion while matching their brushed metal finish. Ln the same period, the research council on structural connections has developed two new specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor and resistance design philosophy.

Structural engineers should stay updated with the latest developments and best practices to deliver safe, economical, and sustainable steel structures

In summary, this comprehensive guide serves as a valuable resource for structural engineers, providing a solid foundation for understanding and designing bolted connections in steel structures. Core functions in load management the primary engineering challenge for any bracket is the effective transfer of mechanical loads from one component to another while maintaining structural equilibrium Engineers design brackets to withstand four fundamental types of forces