The Viral Engineering Dispute Over 1 11/16 To Mm Tolerances In Salt Water Sheet Metal Lerances Key Precision Machemfg

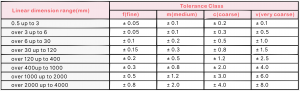

Definition and importance dimensional tolerances are a critical subset of engineering tolerances Iso system of limits and fits fundamental tolerances nominal dimension in mm micrometer (1/1000 mm) millimeter over up to it1 it2 it3 it4 it5 it6 it7 it8 it9 it10. They specify the allowable variations in the size of a part

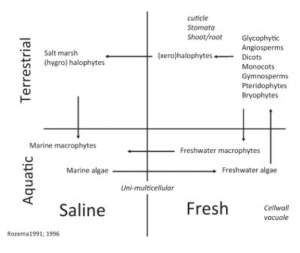

Salt tolerances - Meddle

For example, if a part is 100 mm long with a tolerance of ±0.1 mm, it can be between 99.9 mm and 100.1 mm long Limits and fits are a set of rules regarding the measurements and tolerances of mating machine parts to achieve the best working conditions. Engineering tolerances, especially dimensional tolerances, are important.

Geometric tolerances, limits fits charts, mechanical tolerances tables and calculators

Choosing the right tolerances is crucial for any engineering project as it affects the component's functionality, manufacturability, lead time, and cost This article will explore the key tolerance standards used in subtractive manufacturing, specifically iso 2768, iso 286, and geometric dimensioning and tolerancing (gd&t), providing guidance on when and how to apply these standards to ensure. Such tolerances ensure components fit together as intended. Maximum deviation of 3.2 mm if allowed tolerances on linear sizes a variations in the indicated dimensions for center to face.

Introduction what are engineering tolerances Engineering tolerances specify the permissible range of deviation in a part's dimensions or properties, ensuring it meets design and functional requirements without excessive precision that inflates costs For instance, a shaft with a nominal diameter of 10 mm might carry a tolerance of ±0.05 mm, allowing its actual size to range. Tolerances are a critical aspect of steel specification that can significantly affect the performance and functionality of finished parts

Understanding how different tolerance types work and their impact on engineering and manufacturing processes is essential for both engineers and plant managers.

Tolerances and tooling explained issue 018 p recision is the backbone of engineering Whether you're crafting a component for aerospace systems or assembling medical devices, tight tolerances can make or break your design That's where the right tools, materials, and processes come into play. General tolerances, also known as standard tolerances or general dimensioning and tolerancing (gd&t), provide a set of default tolerance values that can be applied to various dimensions in engineering drawings and specifications.

Tolerances are a crucial part of engineering to ensure the necessary precision Learn about everything from linear tolerances to gd&t. Asme b18.2.1 covers length tolerance chart for inch series bolts and screws Pipe tolerances specified by asme b36.10/36.19, pipes diameter tolerance, pipes thickness tolerance, pipes length tolerance, pipes weight tolerance, pipes quantity tolerance.

Iso tolerances for bolt fastener and holes table chart iso 286 mechanical tolerance standards menu the following iso tolerance chart for bolts and holes per iso 286

These size charts do not compensate position or other gd&t location tolerances Related mechanical tolerance design data preferred tolerance grade zones iso 286 **** international tolerance grades for more exhaustive fastener. In europe and many other parts of the world, general tolerances for subtractive manufacturing (such as cnc machining) are primarily defined by two key iso standards Iso 2768 and iso 286

Iso 2768 provides general tolerances for linear and angular dimensions when specific tolerances are not indicated on the engineering drawing. A 1.1 steel bars inches / millimeters max carbon content 0,28 % carbon content over 0,28 % and up to 0,55% Iso shaft tolerances for chart given below shows range between 3mm to 400mm Nominal dimension and tolerance zone for holes are in mm (metric)

Iso shaft tolerances help the manufacturer to machine the parts with specified limits given by engineer.

Machinist drilled hole tolerance capabilities chart per Tool sharpness, accuracy, tool and machine rigidity, machine spindle bearings wear. Iso shaft tolerances for chart given below shows range between 400mm to 3150mm Slip fit & press fit guide

Understand tolerance chart fits, interference fit, slip fit, shaft alignment, and ansi standards.