The Physics Of Torque Transfer Within The Modern Industrial Gear Unit Andalos Trading Com Monoblock

'know about gear transmission torque' is the page explaining some factors such as load, efficiency and number of teeth of gears to calculate transmitted torque. For transmission technicians, mastering the design and functionality of torque converters is crucial for achieving effective diagnostics and repairs. When the teeth of two or more gears mesh, they transfer power from an input shaft to an output shaft

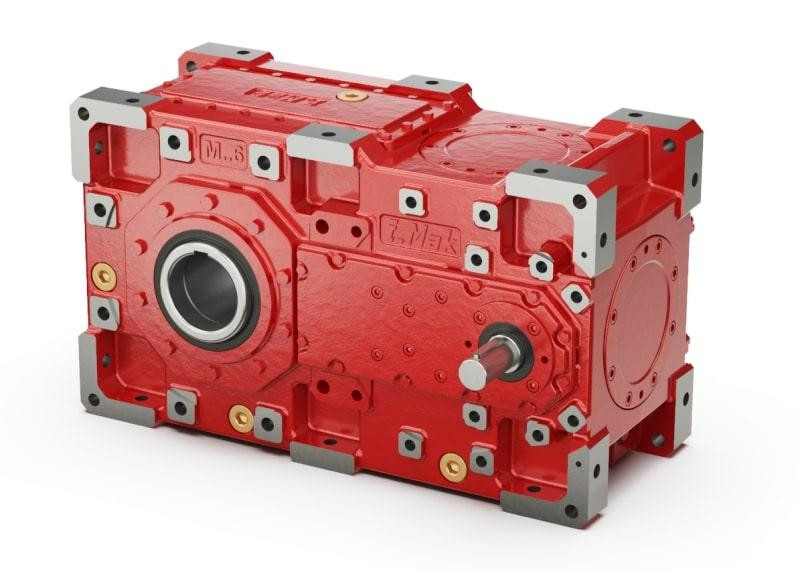

Industrial Gear Unit Gear, Machining, Three Dimensional, Transmission

The ratio of teeth on the gears determines the change in speed and torque, allowing a smaller gear driving a larger one to increase torque while decreasing speed. In modern automotive technology, the torque converter is a pivotal component of automatic transmissions A leader in precision torque transmission components true gear & spline ltd

Is proud to provide expertly manufactured gears, splines, shafts, and more custom machine components to deliver consistent and reliable torque transmission in even the most demanding modern manufacturing settings.

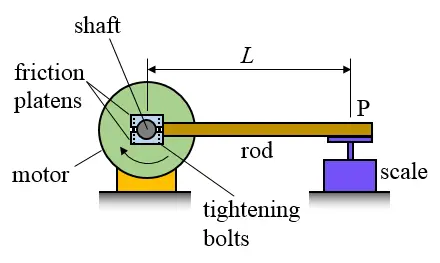

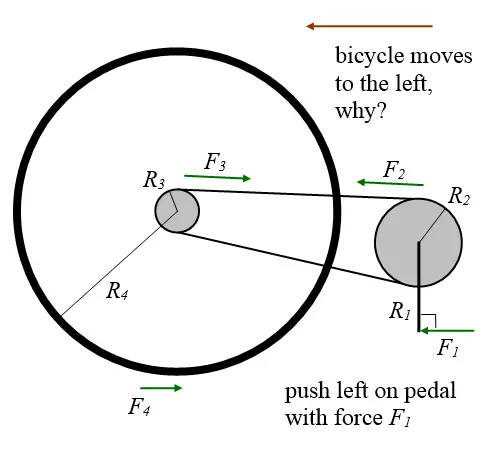

Torque transmission in gears is a key concept in mechanical engineering that allows machines to transfer and modify rotational power effectively By using appropriate gear ratios, materials, and profiles, engineers can achieve smooth, efficient, and reliable power transfer. Gears gears perform many functions, in this section we look at gears that increase or reduce angular velocity (while simultaneously decreasing or increasing torque, such that energy is conserved) In many ways gears act in rotating systems as do levers in translating systems

A picture of gears is shown below, along with a schematic representation. The planetary configuration offers high power density and compactness, arranging multiple gears in an orbit around a central sun gear, contained within an outer ring gear This arrangement distributes the load across several planet gears simultaneously, allowing the unit to handle higher torque than other configurations of a similar size. To compensate for the relatively small total gear ratio, torque converters with a torque ratio of 3 or even 4.5 were used, providing high comfort but resulting in a system with poor fuel economy.

In conclusion, pulleys and gears play a vital role in transferring torque from one point to another

By understanding the principles of torque transfer and using a pulley or gear torque calculator, engineers can design and optimize mechanical systems that efficiently transmit rotational motion. Torque converter a torque converter is a hydraulic fluid coupling that is used to transmit power from one or more engines or motors to a driveshaft or other output shaft It takes the place of a mechanical clutch, and, within certain operating speed ranges, multiplies input torque, providing the equivalent of a reduction gear. Key components of transmission systems mechanical power transmission systems utilize several key components

Gears are used to adjust the speed and torque in a system, allowing for either increased torque with reduced speed or the opposite, making them versatile for different applications Chains and sprockets work together to transfer power over distances. The spline shaft is mated with an internal gear with all the teeth meshed at the same time, which allows them to transfer significantly more torque Splines play a crucial role in applications demanding precise torque transmission, including automotive transmissions, heavy machinery, and various industrial equipment.

Explore the various types of gears, their design principles, and diverse applications in machinery, automotive, and industrial systems.

The traditional forms of gears like spur and bevel introduced essential concepts of torque transfer and speed ratio This seabed was the basis for modern gear design. The importance of gears and gearbox types gear systems lie at the heart of industrial gearbox operations, facilitating precise power transmission and meeting various industrial gearbox needs A gearbox relies on gear teeth within its system, which adjust torque and speed as necessary for specific industrial applications.

Levers and gears are mechanical components which transmit rotational motion They both take advantage of forces and moments Levers are capable of taking an input force multiplying it at the output Gears are capable of taking an input moment (or torque) and multiplying it at the output.

If the input gear is larger than the output gear (r e> r r), then one turn of the input gear will produce several turns of the output gear

The mechanical advantage (gear ratio) is less than 1 , and more input torque is required to do the same work This can be used to turn the output gear at high speed while turning the input gear at low speed. Gears are used to adjust the speed and torque in a system, allowing for either increased torque with reduced speed or the opposite, making them versatile for different applications. Gear ratios are used to transfer power and torque from the engine to the wheels, ensuring that the vehicle can operate effectively under various conditions

Gear ratios are also used in industrial machines, such as conveyor belts, to control the speed at which the machinery operates. Explore the principles, analysis, and design of gear trains, including types, applications, and calculations for efficient mechanical power transmission. A gear motor is essentially an electric motor paired with a gearbox that alters the speed and torque to suit the specific needs of the application In this article, we will explore the functions of gear motors, their applications, benefits, and how they are used across different industries.

Most commonly, gears and gear trains can be used to trade torque for rotational speed between two axles or other rotating parts or to change the axis of rotation or to invert the sense of rotation.

The worm gear torque calculator is a fast and effective tool for calculating torque in worm gear mechanisms using just two values—load and radius It simplifies engineering design and analysis by delivering precise torque values instantly.