How Future Water Infrastructure Will Utilize The Redesigned Jaw Type Coupling H Highest Torque Lovejoy A Timken Company

Water engineering professionals can use our solutions to plan and design smarter systems, predict demands more accurately, and modernize processes, improving outcomes and managing risk and compliance across the entire infrastructure lifecycle for years to come. Typical spiders that do fail will result with metal on metal collision and abrasion, utlimately resulting in required maintenance in the future It helps jaw coupling to effectively transmit torque, reduce impact, and minimize vibrations and wear on the connected parts

H Type – Highest Torque Jaw Coupling - Lovejoy - a Timken company

Jaw couplings come in various designs, including both curved and straight types, to suit different operational requirements. We have lovejoy coupling spider in stock as well. A central location where the general public can locate the latest information and resources relating to the infrastructure investment and jobs act (iija) water infrastructure initiatives and projects.

Jaw couplings play an essential role in ensuring this efficiency by connecting two shafts while compensating for misalignment and damping vibrations

Widely used in industries such as automotive, mining, and power generation, jaw couplings are indispensable components for reliable machinery performance. Access recording 2050 video technology innovation for the future of water in 2050, new drinking water, wastewater, and water supply challenges will demand advanced technologies The water sector must innovate new solutions for water treatment, source water protection, water reuse, desalination, updating aging infrastructure, and much more. Local municipalities water workers will be working hard in 2025 to install infrastructure upgrades

Modernization is long overdue, and the consequence of holding onto the old is stalling the implementation of the new How will cities and utility companies collaborate to ensure the coming year breathes new life into water infrastructure? Water infrastructure and water purity are a top focus for government leaders throughout america With construction timelines ranging from late 2025 through 2028, the projects detailed.

Utilities must balance new water technology with practical needs when it comes to upgrading water and wastewater infrastructure

Here are some of the challenges and innovative water solutions. The jaw flex rrl type coupling consists of 2 standard hubs with 1 rubber spider element. Misumi offers free cad download, short lead times and competitive pricing Quote and order online today!

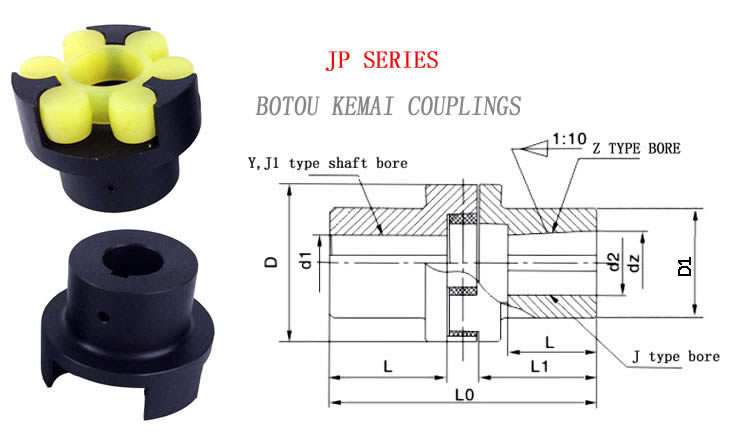

We are the leading manufacturer of jaw & star couplings in india since 1983 utilizing the most advanced technology to manufacture our couplings. Jaw type coupling selection process jw selection process information necessary before a coupling can be selected Shaft sizes of driver and driven equipment and corresponding keyways formulas The lovejoy jaw type coupling is available in a variety of metal hub and insert materials

Hubs are offered in sintered metal, aluminum, bronze, steel, stainless steel, and ductile iron.

The l type jaw coupling, c type jaw coupling, and tl type jaw coupling are the most commonly used types of jaw couplings Jaw couplings are commonly used in motor drives, pumps, and conveyors, where they provide flexibility and help to reduce wear and tear on the coupling and other equipment. Stock jaw couplings jaw coupling selection procedure determine service factor by matching driven unit with prime mover in service factor guide. A fluid coupling is a hydrodynamic device that transmits mechanical power from a driving impeller to a driven impeller or runner by accelerating and decelerating the hydraulic fluid

Types of rigid shaft couplings different types of rigid coupling are Sleeve or muff coupling split muff or compression coupling A jaw type coupler will be perfect because we can use two different jaw parts I have had great success using lovejoy l series couplers for applications such as these

We first need to size the jaw part of the coupler and we do this by calculating the torque.

Jaw shaft couplers do this by having a mechanism, the spider, to connect two jaws One jaw connects to each shaft and the spider slips between the jaws Great reasons to use jaw couplers include the following Allow for some misalignment (let's face it, it is tough to get shafts to align right!)

The l type lovejoy jaw coupling coupling consists of two standard l type hubs and one spider Unless stated otherwise, hub torque and horsepower ratings assume a sox (nbr) rubber spider is being used L150 type couplings is available in stock in our india warehouse