The Physics Of Axial Load Support Within A High-performance End Bearing Understnding Bering Nyz

A bearing supports many different load combinations but most types of application loads can be boiled down to these four main groups Bearing axial load is a force applied parallel to the axis of a bearing or mechanical. Radial loads axial loads preloads centrifugal loads this article will discuss these four types of application loads, how it affects the bearing and what bearing to choose that will best support the application load.

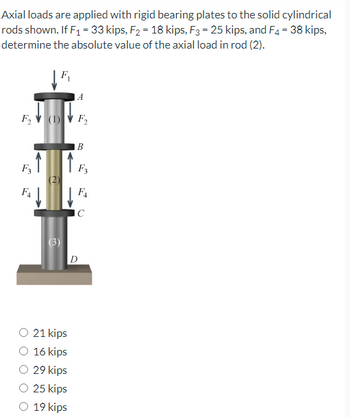

Answered: Axial loads are applied with rigid bearing plates to the

Shaft and axle supports abstract supports of shafts and axles are designed to support the rotary or rocking motion of the shafts and axles and transfer forces from them to the housing What is bearing axial load The accuracy of the action and the reliability of the mechanism as a whole largely depend on the design of the supports

Supports designed for the perception of radial or combined (radial and axial) loads are.

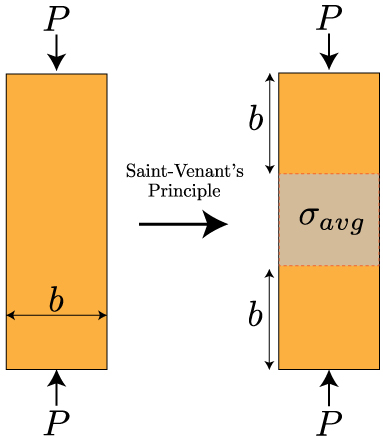

Bearing axial load is a force applied parallel to the axis of a bearing or mechanical component It plays a crucial role in the overall operation of the system in which the bearing is used, directly affecting its performance and efficiency. Understanding bearing loads is key to mechanical systems that depend on precise load determination for performance and bearing life Bearings efficiently handle predicted forces without causing undue stress, deformation, or wear when axial, radial, combined, and centrifugal loads are accurately calculated.

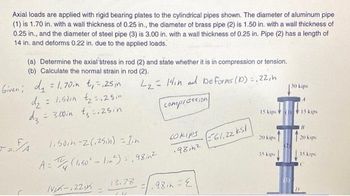

Learn what axial loads, why thrust bearings matter, and how to prevent failure Find the right type for your application and ensure reliable performance. To determine the support reactions when these reactions cannot be found solely from the equations of equilibrium To determine the effects of thermal stresses.

This last equation can be used to directly find the change in length of an object subjected to an axial load

In practice, multiple axial loads may be applied to the bar. At high axial loads, two angular contact ball or roller bearings are installed in the fixing support This increases the rigidity of the system and almost completely eliminates the axial play of the shaft. In this blog, get understanding of how load and speed interact with your bearings and make all the difference in machine reliability.

They can only support axial loads of between 10 and 30 per cent of the bearing's static radial load rating due to the shallower raceways. Axial load is a critical concept in the field of engineering, particularly in structural, mechanical, and civil engineering It refers to the force applied along the axis of an object, affecting its strength, stress distribution, and overall stability. Explore the essentials of bearing loads with nyz, including radial and axial loads, their impact on bearing performance, lifespan, and maintenance.

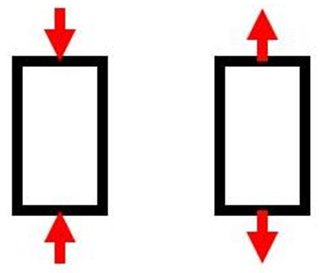

Radial loads act perpendicular to the shaft, while axial loads act along the shaft's axis

Matching the bearing to the load type—e.g., roller bearings for radial, thrust bearings for axial—is essential for optimal function and longevity How does misalignment affect bearing performance? For example, the axial force of a helical gear or the weight of a suspended load in a vertical motor applies an axial load to the bearing While radial loads act perpendicular to the shaft, axial loads are distributed equally among the bearing's rolling elements.

Load type (radial, axial, moment or combined) First, identify the type of bearing required for the application Understanding the nature of the load, whether it is radial, axial, moment, or a combination of them, is critical to selecting the proper bearing. In many cases, the load is obtained by multiplying theoretical values by the load coefficient.

Bearing axial load is a force parallel to the axis of the shaft, acting on the inner or outer ring of the bearing, sometimes called a thrust load

Typically you will find axial loads directly aligned with the shaft, just like a drill bit. + improved rib contact = improved performance and longer operating life we developed the tb roller to significantly increase the bearing operating life under axial load Summary axial bearings play a crucial role in handling high axial loads and are essential for the efficient operation of machinery Whether in the automotive, wind turbine, or industrial machinery sectors, selecting the right bearing is vital for the stability and efficiency of mechanical equipment.

Explore the crucial roles of radial, axial, and centrifugal bearing loads and their impact on machinery efficiency and lifespan. Understanding bearing axial load is crucial for ensuring the proper functioning and longevity of mechanical systems that utilize bearings This article delves into the intricacies of bearing axial load, its impact on system performance, and best practices for its management