How Future Wind Turbines Will Utilize Advanced Types Of Shaft Couplings A Comprehensive Guide To Different

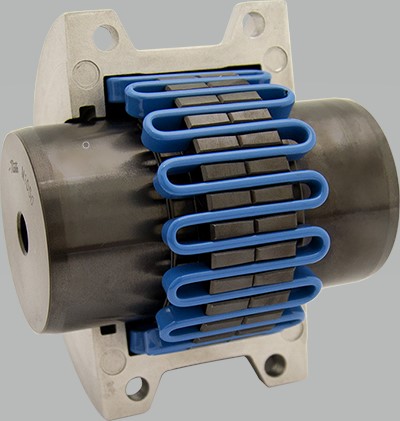

The future of mechanical couplings in wind turbines lies in the integration of advanced materials and smart technologies Couplings mechanical couplings connect shafts so one can transmit rotational power to the other These trends aim to improve efficiency, reduce maintenance costs, and extend the operational lifespan of wind turbines.

A Comprehensive Guide to Different Types of Shaft Couplings

Wind turbine couplings are vital components that connect different parts of a turbine's drivetrain, ensuring smooth power transfer from the blades to the generator What challenges do couplings and torque limiters face in wind turbines Shaft couplings are an integral component of wind turbines, playing a critical role in their efficient operation

What is a wind turbine coupling

Couplings for wind turbines are mechanical components that connect the drive train of a wind turbine and enable reliable transmission of rotary motion from the rotor shaft to the gear unit or directly to the generator. In wind turbines, shaft couplings play a crucial role in transferring power from the rotor to the generator In this article, we will discuss the various types of shaft couplings used in wind turbines and how to choose the right one for your application. Miki pulley designs and manufactures a broad range of high precision motion control.

Why are couplings important in renewable energy systems Couplings ensure efficient torque transmission, reduce vibration, and protect equipment from misalignment and overloads What type of coupling is best for wind turbines Advanced shaft coupling designs are vital for enhancing torque transmission in various applications

Understanding their types, materials, and future trends can help engineers and technicians make informed decisions, leading to improved efficiency and reliability in mechanical systems.

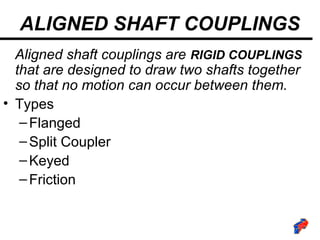

Types of shaft coupling, its uses, drawings, and applications, and more also download the pdf file of this article. Mechanical couplings connect shafts so one can transmit rotational power to the other Shafts are never perfectly aligned so the coupling tolerates slight misalignments, but only to a degree There are three types of misalignment

The center lines of the shafts might be parallel but offset, the centerlines might form an angle, or the distance… They are used in mechanical systems to transmit power such as pumps, generators, compressors, and motors How does a coupling work Couplings connect two shafts, transferring power from a motor to another shaft

They are easily replaceable and upgradeable, accommodating slight misalignments between the drive and driven shaft.

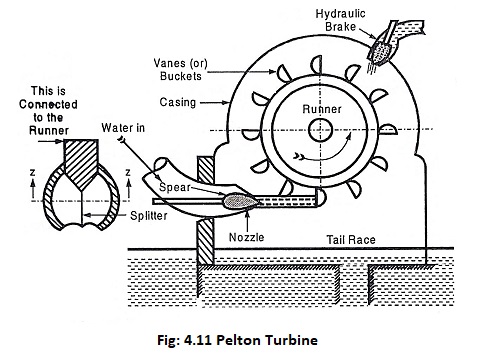

Shaft couplings are widely used in various types of generators, including diesel generators, wind turbines, and hydroelectric generators, to ensure efficient power transfer and operational reliability. Shaft couplings are mechanical devices used to connect two shafts to transfer power from a driveshaft to a driven shaft They are designed to absorb any misalignments or errors between the two shafts, which may be caused by changes in temperature or deterioration over time. Flexible gear coupling for wind turbines introduction to flexible gear couplings flexible gear couplings play a pivotal role in the efficient operation of wind turbines

They are designed to connect the shafts of the wind turbine's gearbox and generator, accommodating misalignments and reducing mechanical stress Understanding the mechanics the design of flexible gear couplings allows them. Wind turbines are devices that convert the kinetic energy from wind into electrical energy Learn more about its types, applications & benefits.

The skf hydraulic coupling, for wind turbines (okck) is designed to fit within limited space, and yet still maintain the benefits of more traditional skf ok couplings

Quick and easy mounting and dismounting It is designed to create controlled high pressure against the shafts without leaving any tooling permanently in place. Universal couplings are widely used in various applications, including turbines, where they ensure efficient power transmission and enhance the overall performance of the machinery. During power transmission, couplings can absorb shock, vibration and heat due to which they are important in many mechanical applications

8 types of couplings different types of couplings are designed to meet different industrial needs Every type has its own characteristics suited for particular use. Polyurethane (pu) couplings are highly important mechanical parts that connect shafts across various applications Owing to their unique characteristics, pu couplings have several advantages over traditional materials

This detailed guide explores the features, benefits, applications, challenges, and future of pu couplings

What is a polyurethane coupling The polyurethane coupling is a. Shaft coupling types introduction shaft couplings are essential components in mechanical systems, facilitating the transfer of torque between shafts Understanding the various types of shaft couplings can significantly enhance the efficiency and reliability of machinery

Rigid couplings rigid couplings are employed in scenarios where precise alignment is crucial They offer a solid connection.