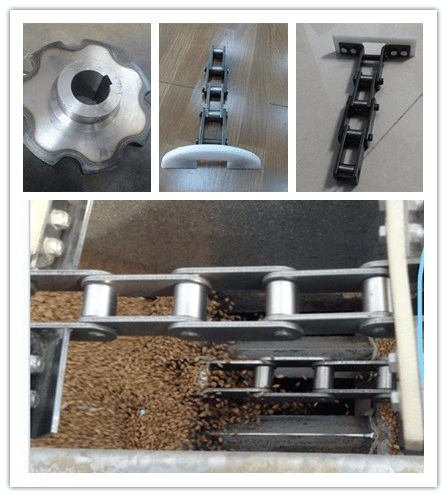

The Wear Resistance Analysis Of Case-hardened Industrial Chain Parts Conveyor

This research aims to investigate and improve the surface hardness and wear resistance of the roller chain parts, which will result in the chain lifetime extension. So, what are case hardening steels, in which areas are they used, and why are they preferred? This failure analysis study is carried out using the methodologies of metallographic analysis, scanning electron microscopy (sem) analysis, chemical composition analysis and hardness.

Wear resistance | verope

These parts experience significant wear and tear due to constant motion and high stress, and the hardened surface layer from case hardening increases their resistance to abrasion and fatigue. The surface hardness, durability, and wear resistance of these steels make them an ideal choice for many applications Elements which are carefully designed according to fatigue strength and wear resistance

Rease the life of cane chains, the resistance of the surface failure should be increased

In this investigation, experiments were carried out to ev Luate the wear resistance using wear test rig designed and manufactured f. Case hardening is a heat treatment process designed to improve the wear resistance and fatigue strength of metal parts The process starts by heating the metal to a high temperature and exposing it to elements like carbon or nitrogen, which penetrate the surface layer.

Learn the differences between case and through hardening—two heat treatment methods that boost roller chain durability, strength, and wear resistance. This process ingeniously merges the advantages of soft and hard metals into a single component. These applications benefit from the combination of wear resistance and impact toughness in abrasive environments. Main aim of this research work is to conduct a metallurgical investigation of failure analysis in failed bearing and chain parts

The failure analysis is carried out by chemical analysis,.

This changes the surface's microstructure, creating a hard case that improves resistance to wear, while the inner core stays softer and ductile. Superior strength, toughness and wear resistance for automotive, industrial and heavy machinery applications Case hardening transforms cnc machined parts when surface wear, impact resistance, or fatigue concerns justify the treatment investment Success depends on proper material selection, geometric design, process matching, and economic validation against total ownership costs.

This dual characteristic of a hard exterior and a tough inner core is essential for components that need high wear resistance and toughness, such as gears, camshafts, and various machine parts The purpose of case hardening the primary objective of case hardening is to improve the wear resistance and fatigue strength of metal components. The quenching process generates tensile residual stresses throughout the material, increasing the risk of cracking or warping. Chain links * material 18mncrb5 (1.7168), drop forged, high precision machined, high wear resistant, case hardened to approx 61 hrc, dimensions 142 mm (normal and reinforced) brand buhler on request other dimensions and materials available on request

Case hardened nitrided steel is a type of steel that has undergone a surface hardening process called nitriding to improve its wear resistance and fatigue strength.

Most structural components perform adequately with standard 1018 or 4140 steel at lower cost and better machinability. Overview of surface hardening surface hardening is an essential metalworking process that enhances the wear resistance and surface hardness of metal parts while preserving their core ductility and toughness. Case hardening, an essential metallurgical process, transforms metal components and their functionality across industries by increasing surface hardness and offering wear resistance and fatigue strength solutions in engineering applications This introduction to the case hardening dives deep into its fundamental processes, types, and most crucially used applications, so enjoy reading

Premium gb 20crmnti case hardening steel from metalzenith Superior hardenability, wear resistance for automotive, machinery applications Case hardening steels are a special type of steel that holds a significant place in the industry